As explained in

the previous pages there are several tasks that can be executed

to keep the DISK II drive in a good working shape.

Some of the tasks are rather simple like cleaning the

drive from dirt and applying some grease to the sliding parts to

ensure smooth

working or adjusting speed of the diskturning within

the correct limitation, some tasks require advanced knowledge

and tools like

adjusting the track zero - and the same is valid to adjusting

the read/writecycle..... this task can only be solved with

advanced electronic

equipment: you will have to use a oscilloscope to be able to

judge the signal at the analogPCB and you should have experience

in using

the scope ....... its also recommended to download the

Circuitplans of the DISK II from SAMs from the site of asimov.

Again i will first give an intro with some basic explenations

for better understanding of the technical details:

We all probably remember that experiment out of the old

schooldays when a copperwire was wound several dozends of time

around

a steelnail and applying some DC-Voltage to the wire .... and

the steelnail became magnetic while the current was applied -

and after

disconnecting the current the steelnail was not magnetic

again.... - well that was a demontration in large to the effect

of electromagnetic

field. The same happens in the read/write head of a

taperecorder and of course also the operation within the

read/write head of a diskdrive

is similar too..... the big difference is the scale of

that..... just for fun a graphic to show that difference:

and as a result of the

different sizes of those electromagnetic coils the electrical

values of voltage differ same scale:

the read/write-head of a cassetterecorder delivers to the

electronic of the PCB some voltage about to maximum of 10

millivolt

( thats 10 thousendth parts of 1 volt or in numbers 0,01 Volt ! )

and the coil of the DISK II passes only 0,5 millivolt to 0,7

millivolt while reading

the contents from the disk. In both cases the information must be

amplified up to a value that can be passed to the level the

electronic can use...

Within the cassetterecorder the audioamplifier needs an input of

about 0,7 Volt to amplify the output to the speaker with some 6

Volts.

At the DISK II the required voltage must be amplified up to at

least 4,5 Volt to clean the signal and pass it with 5 Volt to

the controller of the computer !

And one of the important things to know is the fact that the "basic

noise" from tape or disk will deliver some 0,002 to 0,003 Volt

while reading -

compared to the voltage of 0,01 at the taperecorder and to the

0,0006 Volt at the DISK II - and if you amplify the signal of

course the noise is amplified too !

The following picture will visualize this explenation:

|

In later years the

chipmanufacturers designed special chips for the disk

read/write-heads with integrated special filters to split off

the "noise" at that

very low voltages and to amplify only very selected frequencies to

enhance the ability of reading data from a disk .... that was

the very moment that

drives could be developed with more than 40 tracks ( maximum of 360

kB per disk to 2 sides with 80 tracks and maximum of 640 kB per

disk ) and the

ability to create diskformats with larger compression of data ( the

step upwards from double density to high density with the

advantage of storing

1,44 MB to a disk instead of the former limitation to 640 kB ).

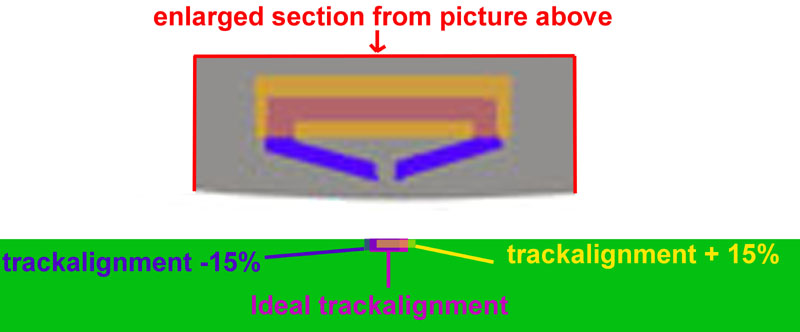

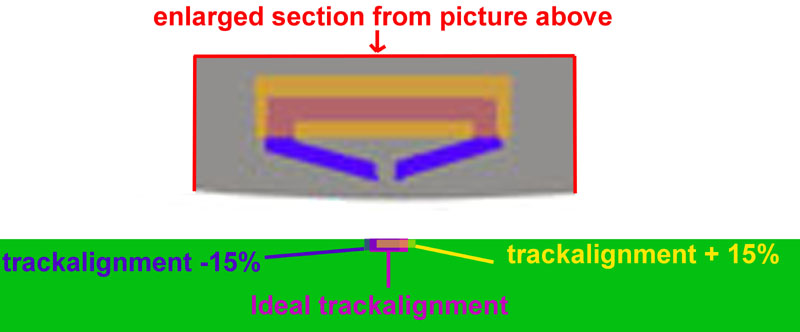

And just beside of this you also should bear in mind that with the given

trackwidth also at the trackalignment a tolerance of 10% to 15%

is permitted

by standard definition. To explain that relation of that to this topic

lets see the next picture:

|

This means in

"worst-case-scenario" that if a track is written by a drive

aligned with -15% and thereafter a disk with an alignment of

+15% tries

to read the information the head will only read 70% of

the track and 30% of the empty ( but noisy ) disk besides.....

and this of course will also

have affect to the electrical signal by giving the read

information only 70% of trustable information and 30% of trash !

But now just an

additional fact:

The adjustment of the electronic at the analogboard is

also drifting by another +/- 15% too (!) given

by the tolerance of the used components !!!

All facts together make the difference

between a diskdrive that "reads nearly everything without

mistakes" and a drive that has

at least some 2 % or 3 % of read errors and therefor is forced to

recalibrate more often while reading to finaly get the demanded

information from the disk.

So now after the basics lets get into the hardware and the electronical

task at the analogboard starting first again with a picture

shown in the page before:

|

Our attention will be fixed to the 2 variable yellow resistors with

the light blue spintops at the bottom of the picture marked as

R33 and R 28 ( in the drawing also

the one indicated with the blue line and the other marked by the

light green line ). Within the circuitplan they are marked by the

enlarged red spots.

For the measurements the testpoints TP2, TP5, TP6 and TP7 will

become important. That will be the related points to view during

the adjustment of the

signals with the 2 resistors the signals at the scope. In the

following part of this page the measurements will be commented

with good examples and bad

ones.

|