I have a ROM3 IIGS and I wanted a wDrive to complement my BOOTI card for track/sector ordered disk images, which the BOOTI card doesn't support. The thing that intrigued me about the wDrive vs Floppy Emu is that the wDrive has a menu system you can use via the computer's monitor & keyboard, versus having to look at the tiny OLED display. Not a fan of the tiny OLED on my Pi1541 for my C64.

I purchased a new wDrive and a "tested" Disk II controller card from eBay. I referenced the Disk II controller card manual prior to powering anything up - to make sure I had the controller card oriented properly, and the ribbon cable orientated properly. I put a fresh battery in my IIGS and configured the slot (I tried 4,5,7) in the control panel to "Your Card" and set "StartUp" to the slot I installed it in. I went the controller route because the only IDC20/DB19 adapter I could find ships from Bulgaria (I'm in USA) and Disk II controllers are cheap.

Unfortunately, while the wDrive powers up and I can select images - I've never been able to boot from it - the machine hangs like its spinning the emulated disk drive with no disk in it. I have no IDC20 to DB19 adapter to further test the wDrive with. So, I purchased a Disk II drive locally to test the card and it booted up immediately with the Disk II controller card from eBay - so I'm pretty sure at this point the controller is good. Other things I tried are two different SD card brands, low level formatting SD cards with SD Card Association's official formatting tool, and I tried images that worked with ADTPro on real disks.

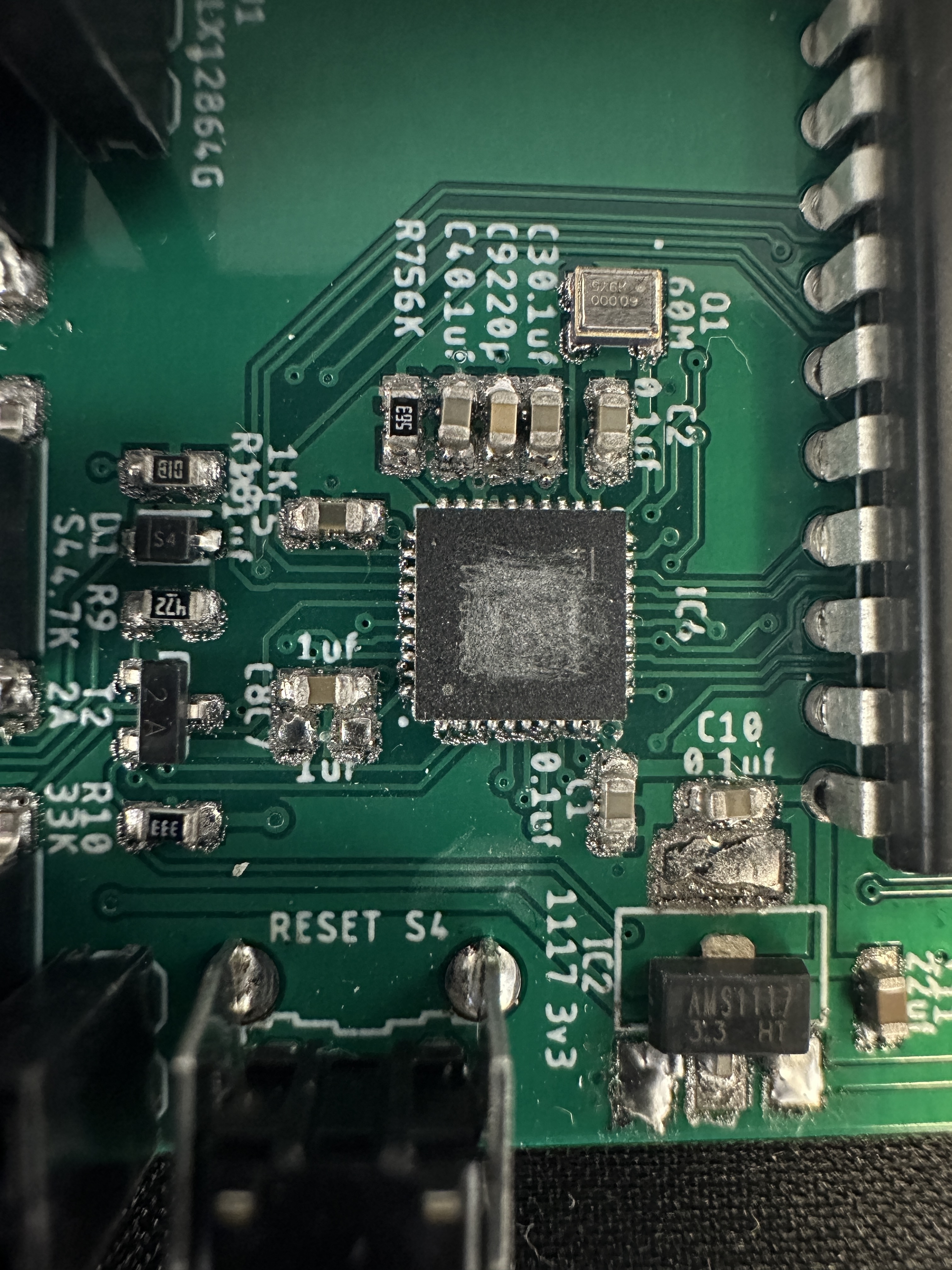

I'm waiting on an IDC20/DB19 adapter from a2heaven. I have reached out to the wDrive seller - I was advised to wait on the IDC20/DB19 adapter and we'd go from there, but the wait is agonizing :) Since I'm kind of at a dead end, I decided to peek inside the wDrive because its 3D printed enclosure just snaps together. I've only ever done through-hole soldering, not SMD so I'm not 100% sure what I'm looking at. My initial reaction is that I'm unimpressed with the soldering job versus many other retro hardware items I've purchased - but I can't prove this is the source of my issues. It looks like several possible solder bridges, but my multimeter probes are too large to test the pins on the microcontroller. I can tell the row of four SMD capacitors are all bridged together. I was surprised to see the microcontroller's markings scraped off, perhaps to keep others from copying the design?

Any other ideas I should try to get it to boot?

NOTE: in the images the OLED display is unplugged, it just plugs into those pin headers

I had some issues with mine until I figured out how to format the SD card. Once I got that figured out it has worked great. I got my DB19 adapter from BMOW. I also have 3 FloppyEmus that I use on other machines. One of the older model and two of the newer ones.

I agree that the soldering job on that looks awful. I have never opened mine so I can't say if it is better or worse.

Edit to add... just opened mine up and the soldering job in mine looks very professionally done...

So my first thought is holy crap, totally agree that looks like a really bad solder job. Tough to tell from the photos, would need to look under a scope to be 100% sure but from this view, looks like solder ball party and not good. Given what I see with the big pads, I too would have questions about the fine pitch leads.It would be interesting to see the back of the board, I expect all the through hole joints to be pristine... but that's just a guess cuz it would be more insane if bottom is perfect. Did you scratch out the markings on that chip?

If the board is really that bad... I don't think your screen would even be working. Without a schematic a good guess, would be to check if the pad for C7 closest to the chip is shorted to the same pad for C8. The other ends (label side) should be shorted togeter with both at ground. I think the same for caps 2,3,9 which appear to share ground (on the label side) but the other ends likely should not have continuity. If C7 pad is shorted to C8 pad that NonPopulated C7 is really going through C8. I would normally suggest grabbing a rework station and reflowing the solder, but in this case... no if it's as it looks there's likely more crap hidding out if sight.

Did you share your photos with them?

That might be the worst solder job I've ever seen on a commercially sold product. Whoever built that board should be shot.

And I will add that it's become fairly typical (and with a fair amount of irony) for chip markings to be sanded off on "far-east" designs.

It looks like reflow wasn't done with the correct time/temperature curve or the wrong solder paste was used.

Given that, it is quite possible that small balls of solder got trapped under components like the QFN processor chip, in addition to the visible bridging. Something of a wonder that you get any life from it.

I didn't expect these reactions, I wasn't sure it was that obvious this is why my wDrive doesn't work.

I sent photo to USA resller for wDrive, and within minutes was given a full refund and told to toss the unit and not bother sending it back. We were waiting on IDC20/DB19 adapter from a2heaven for further troubleshooting. They would follow up with the manufacturer about quality control.

Thanks for everyone's help! Off to order a Floppy Emu instead..

Looking at it again... One of he .1uF caps near the FPGA looks like it is missing entirely. I think it is C7 that jeff d mentioned. Some of the other sloppy soldering could maybe be cleaned up. Not sure what the mess of solder near the 1117 3.3v regulator is supposed to be.

I don't have the skills to attempt to fix it. I've done plenty of through-hole repairs and mods on my Commodores, but my hands are not steady I don't even want to attempt this.

If anyone thinks they have the skills to get it to work, I'd be happy to mail it for just the cost of shipping. I'm in the USA. I was also considering offering the 3D printed case and OLED screen on the A2 Facebook group in case anyone has a unit with a broken case/display - not sure if that would be a better use of it, if the board is beyond repair.

I just opened mine up to look again... no capacitor installed at C7 on mine either, so unless something is bridged like jeff d suggests that probably isn't it.

And damnit... When I opened it up one of the little button pushers went flying and I can't find it even after 10 minutes of looking... Argh. It amazes me how a little part like that can sometimes bounce and roll where it will never be seen again.

That soldering job is indeed incredible. Glad you got an immediate refund. I wouldn't dare to connect anything with such dodgy soldering to my machine. Even if it worked for now - one day one of the countless solder balls would get loose and cause trouble. And then anything could happen.

Interestingly enough, their twitter account shows a photo of how they receive these boards with assembled SMD components - but without the through-hole IC. So they need to solder the DIP IC separately. Whoever did this, should have seen the obvious issue with the PCB.

Anyway, you'll be happy with the FloppyEmu. And if you don't like the small display, you can always upgrade it with a larger 2.42" oled. The latest standard FloppyEmu firmware officially supports the larger displays with a configuration option (so, changing the firmware with an alternate/custom file is no longer required).

If you're willing to send I'd love to look at the board to understand how it works at all. I think softwarejanitor mentioned a couple of the other things that caught my eye but I couldn't even ID what one was so ignored it but would love to know what's there.

As to the C7 missing, it's not uncommon to not populate pads, but as mentioned before if shorted the open path is not open... so many questions and while it may be fun to try and nurse back it's also likely not worth the effort. I'd still like to look a the board, I got crazy tools that I don't use enough. =)

I'll send you a PM about shipping it if you're willing to do that.

I already asked to see if I could get at least one of the pushbutton parts... since I lost mine checking for the C7...

I saw that note about what I'm assuming was a spring induced launch... been there done that plenty of times myself. In fact, I lost one a few weeks ago trying to repair a special butane lighter and even though I had a solid idea where I heard it land on a wood floor I still haven't found it. =( I totally understand!

I wouldn't need the button or its parts. If it's more than the spring/hat/cap and djc6 doesn't want to remove the switch I could do that easily.

It's not really spring loaded... it's just a little 3d printed "hat" that sits on the switch shaft. It wasn't really launched... it just apparently rolled somewhere into some nook or cranny that I've been unable to find it...

It's not really spring loaded... it's just a little 3d printed "hat" that sits on the switch shaft. It wasn't really launched... it just apparently rolled somewhere into some nook or cranny that I've been unable to find it...

This should be a easy enough fix for the right tech. Just go over all the surface mounts with the hot air to get everthing reflowed correctly, maybe take off the chip and check for solder balls underneath and then reinstall the chip correctly.

I just grabbed a modern broken A500 accelerator off ebay with a bad solder joints (That you could actually see in the auction pics.) I had it up and running in 30mins.

Without knowing what led to the improper reflow that is not a safe assumption. As I mentioned earlier, the wrong paste could have been used (such as a HMP solder paste) and in that case no amount of hot air will fix it. The other problem is that paste has a limited open time: the flux loses its effectiveness and ability to wet the solder balls into proper beads and fillets. There is no indication that we know the date the board was "manufactured".

Could it be repaired? Possibly, but the available information doesn't support that.

Actually, that looks a lot like Tin pest (Wikipedia). Sometimes called "tin plague" or "tin disease."

With the rise in lead-free soldering, some boards are soldered with pure tin. Under various conditions, metallic tin can spontaneously convert into powdery non-conductive gray tin. (You've probably heard of "tin whiskers", another more-common problem that occurs with pure tin solder.)

There's a lot of active research into prevention and management of tin pest in RoHS-compliant circuits, but I couldn't find good pictures of affected circuitry so here's a mediocre picture of tin test objects at various stages of tin pest decay:

tin pest.png

[EDIT] According to this academic discussion of Tin Pest, RoHS exemptions do permit the use of lead-solder in some applications that would be vulnerable to tin pest. (Even though there might be other lead-free alternatives.)

Instead of tin pest, which happens over time at very low temperatures (below freezing), it looks like an improperly soldered circuit board assembly. It's not just the SMD components: the 18CV8 through-pin DIP also has dry joints.

I had some great picts under high magnification taken anaylizing some failures, but I can't find those right now. I think there are many reasons for tin wiskers, but perhaps the most common is from dissimilar metals used in connectors (e.g. tin connector mated with gold connectors) and high frequencies may promote growth. Interesting that wiskers have lower resistance than the surrounding metal, which can promote further growth and additional issues. There's also dendrites which can formed in manufacturing, and these can be beautiful structures, I've seen dendrites that look like pine trees! That said, I think we all agree this board's problems are not due to wiskers or dendrites, I wouldn't be surprised if this was one of the first/last in a run.

I'm with robespierre, and wouldn't assume it's fixable. If this is a problem with solder chemistry, that's a no go. The amount of excess solder alone would suggest reflow won't work as you suggested, and reflow may create a few more bridges. In any event, this would likely require a lot of work, more work than the cost of a new board!

Chris Torrance sent me the .stl files for the buttons, so I should be able to get replacements printed.

This is definitely not tin pest. It is simply the result of using expired SMD solder paste. This stuff has a very short shelf life even when refrigerated (usually just a few months), so it's use it or lose it kind of situation. I still have one syringe that I should've lost a long time ago, but sometimes I use it with my soldering iron.

IMG_5587.JPG

Are you the same dabone of Link232-Wifi cartrdige fame? One of the best purchases for my C64/C128 :) And a very high quality 3d printed case!

While some solder pastes do have a short life (not all; Henkel GC10 has a shelf life of over a year at room temperature and longer if refrigerated) that is probably not the cause of the problems seen. What usually happens when the paste is expired is that it "slumps" and gets more viscous and the solder balls begin to concentrate at the lowest point, leading to clogged nozzles (if spot application is used) or poor stencil separation leaving voids (when using stencils).

Note that even long-shelf-life pastes have a short open time ("abandon time") of around 24 hours before the flux is no longer tacky.

You can typically use expired paste like you showed if it is stirred with a few percent of replacement solvent and hand-applied through a dispenser syringe. It would be a bad idea to use it in an automated machine or on a stencil line.

I do not know what method was used on the OP's board: since some manual thru-hole assembly is obviously required (for the DIP chip and switches, connectors, etc) it would not be much more to manually do everything, but many projects now utilize combined PCB and SMD reflow soldering services from JLCPCB etc., simply because the cost is so low.

Yep, that's me.

Maybe it’s not due to expiration, but the SMD paste is definitely the reason. I had a very similar result with my home reflow setup and a paste from AliExpress a few years ago. I always assumed that they sent me expired paste, but it could have been just really low quality. No issues with the one from the picture above though, which I got from Farnell.

Either the last poster pasted the wrong link, or these spam bots are getting very sophisticated.

Going with sophistocated spam bot IMO. Long before chatGPT existed, a software called xrumer was created, and when I worked in a web hosting abuse desk I have to say that even though it's sole purpose (xrumer) is creating fake accounts and spamming forums, I observed that it's inexcusably well written :(. Combine that with stuff like ChatGPT and you can only expect more and more almost-realisitic looking posts from spam bots.