I'm working on a very early Apple II power supply, serial number in the 3000's. I want to restore it to proper working order, with a minimum of fuss to keep it reasonably original and historically accurate. Although I did have to drill out the 2 rivets that Apple decided to use to keep us safe from ourselves. I suppose I could replace them after I'm done.

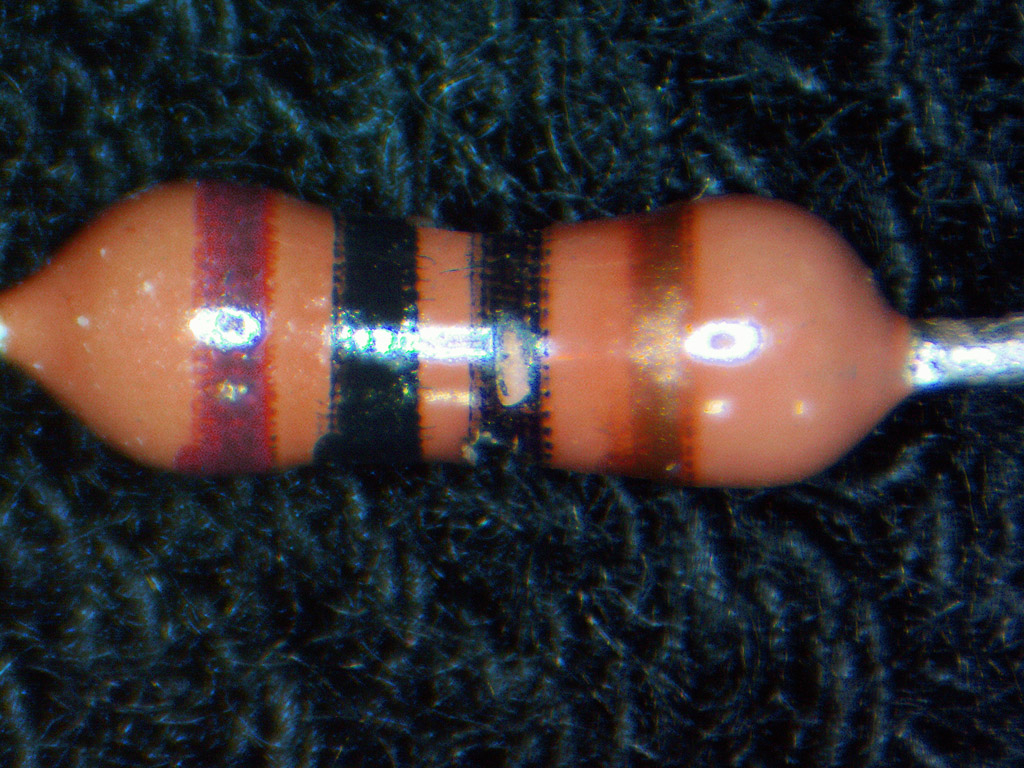

Anyways, the problem is that it has a 1A fuse (soldered) on the PCB of the PSU, and the fuse instantly blows when you power it on with no load. I have found that R22, which is a 10 ohm resistor is exploded. Well, the color bands say it's supposed to be 10 ohms, but it tests as about a 1k ohm resistor on my DMM. See photo below.

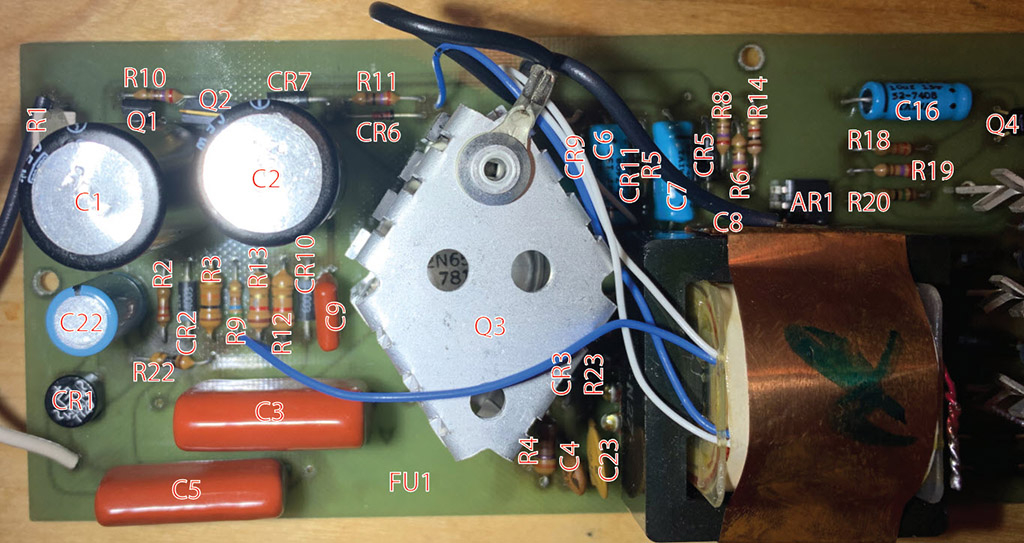

Looking at the schematic for this PSU (see photo below from my copy of Winston Gayler's "The Apple II Circuit Description"), R22 is surrounded by C22 (a 470uF @ 6.3V electrolytic capacitor), Q3 (the large TO-3 switching transistor), among a couple other small signal diodes and resistors. I removed C22 and tested it on my LCR meter, and it tests flaky right after the fuse blows but then if you wait a couple hours C22 tests normal again on the LCR. So obviously I'm going to replace C22, especially given it's low 6.3 voltage rating.

I don't have an easy way to test Q3, but I could rig something up to measure the gain if I had to. The other surrounding components (diodes and resistors) look good and test to reasonable values (in-cicuit FWIW). I'm wondering if I should just order C22 and replace it (and replace the exploded R22) and give it a try. Seems the worst that could happen is I blow another fuse, and I have plenty of them.

Any suggestions from any experts here in switching power supplies? I'm far more skilled in the digital circuit realm, but I'm pretty sure I can get this PSU running again with enough perserverance. Unfortunately I could not find any documentation that identifies the physical components with the components in the schematic. Worse, the schematic doesn't identify the values of the components, so the only way to identify component IDs was to reverse-engineer the PCB layout to match the physical components with the schematic. The schematic and my physical PCB matched perfectly, but it was a tedious task. I've shared my results showing this component annotation in the 3rd photo below.

You don't say so explicitly, but your description implies that you deduced R22 as the cause of the fuse blowing. I don't think that follows from the schematic and measurements.

That fuse position in the circuit is definitely not where a general safety fuse would be placed, so it would be reasonable to think it has a special function based on the circuit topology. Look at the location of the rectifiers CR1, CR2, and CR3. It looks as if the designer used that fuse to protect the transformer (or other components) from shorted rectifiers at these positions. I expect it is a fast or super fast blow type (where a general safety fuse would normally be slow blow due to inrush current characteristics).

When you say C22 tests normal on a LCR meter, do you mean both its ESR and DCR (leakage) are normal? An electrolytic cap can have normal ESR and low DCR if it is damaged. Do you discharge the cap before testing, and is it an in-circuit or out-of-circuit test? These questions come up because it is not normally the case that a capacitor "recovers" the way you are describing. Perhaps it overheats internally and takes some time to return to its normal leakage but this would be a severe overload in excess of nominal ripple current, unless it is already bad from DC leakage.

If we're talking betting odds for failed capacitors, small radial electrolytics have the highest failure rate compared to other sizes and types and C22 is one. However, the fuse blowing cannot be explained by C22 failure.

Q3 collector-emitter short plus leakage on C22 might possibly blow the fuse but I think not the most likely possibility.

Take a look at the Sams Computer Facts - Apple II, II Plus.pdf. It provides oscillograms at various points that you can easilly translate to yours.

Also replace all the electrolytic capacitors with low ESR modern ones. These old ones might get reformed and start working, but this is only temporary. With modern capacitors you also want to go to a higher voltage until their cans are more or less the same size as the original ones. Higher voltage/larger can capacitors have lower ESR, so they will not heat up as much and will last much longer.

By that schematic, just after a quick look if FU-1 is blowing it could be caused by a shorted C3, a blown CR3 or issues with R4,C4, R23, C23, or the foil of the transformer is shorted to ground. Q3 could also be the culprit if the collector is shorted to the emitter or the oscillator circuit is stuck in an always-on state.

Also, have you tested the bridge rectifier out of circuit?

I am certain that R22 exploding is NOT the root cause of the problem; that is only a symptom. I also don't believe C22 is the root cause; I think it failed because it was driven beyond it's 6.3 volt rating by some other circuit problem. From the little I understand about switching power supplies, my theory is that something is causing Q3 to basically stay "on" continuously (rather than operating in a PWM mode to regulate voltage). If my theory is correct, then the question is what is causing Q3 to be continuously "on"? It could be anything really. And it's difficult to troubleshoot because I can't really probe around with my scope while the circuit runs, since it instantly blows the fuse. Since I'm not a switching power supply expert, I figured I would post here.

C22 now tests as having the correct capacitance (356 uF), reasonable ESR (1.7 ohms). The DCR of the capacitor measures 14.2 ohms with my LCR meter-- I don't know if this value is reasonable or not as I've never really measured DCR of a capacitor before (usually I care about it for an inductor).

I can systematically desolder all the semiconductors and test them, then move to desoldering all the capacitors and testing them. But I was hoping to get an expert opinion on a likely root cause before I go to the brute-force method.

Thank you for the suggestions-- I will definitely test each of those things. Anything is better than the brute-force method of desoldering every component and testing out-of-circuit. I really hope the problem is not Q3, as that will be difficult to replace (I think I would need to pillage another PSU for a donor part).

As I said in my previous reply to robespierre, my theory is that Q3 is just "on" continuously, rather than operating in PWM to regulate. It feels like almost anything could be keeping Q3 "on", but I will try your suggestions first. There is no "controller" IC chip in this PSU (to oscillate and adjstust the PWM duty cycle)-- it is all done with discrete components and analog circuitry, which is not my forte. In fact, the only IC chip in the entire PSU is the opto-coupler for the feedback from secondary side to primary side. Heck, even the opto-coupler could be stuck in on/off state and causing Q3 to be always "on".

Thanks again!

R4, C4, R23, C23 all tested okay out-of-circuit.

I then removed some components around the opto-coupler (component AR1) feedback, and discovered that C16 is bad (it almost an open circuit). Well, at least I *think* it's C16.... C6 and C7 are the identical component and it's possible I mixed them up. Does this suggest anything to you? It feels like if there is a problem with the opto-coupler feedback then it could cause the Q3 switcher to be turned on continuously, which would lead to a blown fuse and blown R22/C22.

Here is the fully schematic showing C16 (and C6 and C7).

schematic2.jpg

A DCR below 50 Ω is a very leaky cap. Between 50 and 500 is slightly leaky and a candidate for reforming. A capacitor's DCR is effectively in parallel with its capacitance (whereas the ESR is in series) and so will lead to self-discharge. Another check is (out-of-circuit) to charge the cap using a power supply and then watch its discharge using a voltmeter. If the DCR is really 14 Ω, it will self-discharge almost instantly.

Some component tests need to be done out-of-circuit for confidence, but shorted rectifiers or transistors can be found in-circuit using the diode mode of a multimeter. The expected voltage dropped across a PN junction is around 0.7 V. So when the diode mode is applied from the anode to the cathode of a silicon rectifier, or from the base to the emitter of a NPN transistor like Q3, the reading should be around 0.7 V. A shorted junction reads closer to 0 V: it is not dropping any voltage because it is a dead short. If the junction has failed open or you test it backwards it blocks all current, leading to an OL reading.

The initial signal that turns on Q3 is the AC voltage from the bootstrap winding (the bottom winding on the primary side). Whenever there is current flowing through Q3 from its base to its emitter (meaning that the base is more than +0.7 V greater than the emitter) it begins turning on and conducting through the top primary winding. Since the bootstrap winding provides an AC voltage, Q3 should not conduct more than 1/120 s before turning off regardless of the regulation control circuit. This limits the power consumed and I think the fuse will not blow even if the supply outputs are overloaded (it will simply shut down during an overload).

The fuse is to protect against internal failures on the primary side (so if it blows, there is a catastrophic short circuit and the supply would burn itself up, never mind any of the outputs or feedback mechanisms). Take note of the reply about the transformer shield: the schematic shows an internal shield foil as well as the external shield, but they have 170 V between them (rectified mains voltage)! The transformer itself or its mounting is certainly a potential for causing the short circuit. The rectifiers CR1, CR2, and CR3 can also do this. You may need to remove them from the circuit to find the location of the short without specialized diagnostic equipment.

To begin with, just measure the resistance between Pri+ and Pri- (that would be either terminal of C3). This needs to be at least several kΩ; I don't know what it should be exactly, but the fuse points to a short here. If you find a low resistance, there is definitely a short and not a "feedback into Q3 problem" like you described. First find and fix any short circuits while the supply is OFF before trying to turn it ON.

Note that measuring this Pri+ to Pri- resistance at DC may require more setup than just the resistance mode of a DMM, since there is a low AC impedance from the capacitor bank.

How is it having the correct capacitance when it's supposed to be 470μF?? Old electrolytic capacitors that are still good never go down in capacitance. They always go up as the electrolyte dries. But this increased capacitance doesn’t come free. It comes with decreased breakdown voltage. This is why you should change all electrolytic caps before turning it on again.

And since we are talking about a rare PSU, being recapped doesn’t decrease its value, since it’s expected to be. On the other hand leaving bad electrolytic capacitors can definitely cause other parts to break, and those do make it more valuable if they are still the working originals.

Sorry you're right on the the cap's value, I guess I had a brain fart there, not sure what I was thinking. a 356uF value is no good for a nominally 470uF cap.

No argument from me on the recapping, especially since there seems to be more than one bad cap now. However, I wouldn't recap a supply that was working normally just to recap it. But that's just me, opinions vary of course.

Yes, every situation is different, which is why I avoid speaking in general and try to evaluate things on per case basis.

Sure, C22 is a gonner, no doubt about it. Plan was always to replace it.

I've actually been doing exactly this for the last hour., amd I just discovered that diode CR6 is also bad. CR6 is a small-signal general purpose 1N4150 diode. After removing CR6 and testing out of circuit, my DMM (in diode mode) shows 0.2V in both directions. So almost a short across this diode.

Yes, my DMM is going to see a low DC resistance across the primary DC voltage terminals because the DMM will simply charge C1 and C2. I'm not really an expert it these kinds of analog measurements, so it's likely I don't have the equipment for "more setup than just the resistance mode of a DMM". If you can describe how I would make a more useful measurement, then I would love to know about it so I can do it once I put all the components back on the board, and before I power it up for the first time.

So far, the tally of bad components is: R22, C22, C16, CR6. It's unclear which of these were the root cause, and which are symptoms of the first blow up. I think for sure R22 and C22 are symptoms. Not sure about C16 and CR6 being a possible original root cause.

In many cases where I experienced that, fuses blow instantly on switching power supplies it was the switching transistor / FET that has blown out.

The other 5% of the cases the switching part of the power supply, in this case Q1 or Q2, has problems and doesn't start to oszillate (if this is the right term for it).

In rare cases the rectifier was bad.

Just my two cents.

Sorry for my bad technical english ...

Well, a shorted CR6 will screw up the oscillator, so you're getting close.

While you're testing components out of circuit, I'd be testing Q3 to make sure it's still good.

With CR6 shorted, the feedback from AR1/Q1/Q2 won't have much effect and the base of Q3 will just oscillate at 60 Hz.

When the feedback detector at Q4 is off, that is, 5Vout is high enough, AR1's phototransisor is off, so the base of Q1 isn't getting pulled down. Q1 is therefore conducting, and the Sziklai pair of Q1/Q2 will pull Q3's base down to Pri- through CR7. This effectively cuts off Q3 conducting through the primary winding. Every 1/60 s, the bootstrap winding kicks a little more voltage into Q3's base and it conducts briefly before the feedback cuts it off.

When feedback detector Q4 turns on, because 5Vout is too low, AR1's phototransistor turns on, pulling down the base of Q1. Q1 therefore cuts off, and the base of Q2 charges through R10 and it soon cuts off also. If the AC flowing through R11 is a positive half-cycle, the base of Q3 charges up and it switches on, conducting through the primary winding. During a negative half-cycle CR6 pulls Q3's base low and prevents it switching on, which is why this power supply is only able to conduct half of every 60 Hz line cycle no matter the load.

The function of C22 appears to be to stop the feedback regulating for a short period when the supply is cold started, to allow power to flow into secondary storage capacitors. So Q3 always conducts (during positive half-cycles) for a little while even with no load until C22 is charged.

You know, it's funny, when someone has enough experience that they can cite probabilities about what "usually" goes wrong in some specific situation, then they're often worth listening to. And wouldn't you know it, the 44-year-old PSU is not dead because of aging capacitors. No, the big switching transistor Q3 is in fact blown. It seems likely that even C22 was blown as a result of Q3 being stuck "on". Q3 was the last semiconductor that I removed from the circuit since I had to disassemble a glued-together heat sink cage to get it out. But out-of-circuit, Q3 has low DC resistance between emitter and collector. I actually measured this low DC resistance in-circuit a while ago, but putting the DMM in diode-mode reported non-zero voltages in-circuit, so I chalked up the low DC resistance to being in-circuit with other components. I guess I should keep my day job as clearly I'm no analog circuit expert. :)

Digikey/Mouser seems to have a minimum order of 200+ pieces for 2N6543 transistors. But I looked on eBay and they are available over there for reasonable cost. The replacement 2N6543 won't have a 1978 date code, but I'll live.

At this point, I'm going to remove the remaining capacitors so I can test them individually out-of-circuit, which will then enable me to reliably test all the resistors in-circuit. Then, every component will have had a reliable test. Although, I don't have the test equipment to subject any of the high-voltage components to a full 160 volts, so there will still be some uncertainty when it comes time to turn the PSU back on.

I started this repair hoping I could just fix one or two components and call it a day, since I actually have 3 other Apple PSUs from 1978-1979 and they all still work like a charm. But it was not to be that simple, so I'll just recap all the electrolytics in this PSU and it should last for years to come. I'll post updates with photos as I reassemble things. I'll also re-publish the schematic with component values and BOM, so future troubleshooters won't have to reverse engineer the PCB like I did.

Thank you for that, very nice analysis! When someone explains the purpose of each section of the circuit, then I can follow along quite well. But I do not have the experience and skills to simply look at the schematic of an analog circuit and deduce it myself.

Here's the final tally of bad components. I will recap all the electrolytics during re-assembly.

FU1: 1A @ 250V fuse

R11: 10 Ω

C16: 10 uF @ 15V

C22: 470 uF @6.3V

CR6: 1N4150

Q3: 2N6543

IMG_4085.JPG

It sounds like you know electronics, so this may be best for someone who doesn't understand... or just food for thought.I'm going to suggest something different than CVT who earlier said replace all electrolytics with newer lower ESR caps. I don't totally agree, I agree that you should recap the 40 year old caps with newer ones but that's easier said then done. Many of the caps are used for banking power and why those had original tollerances of -10 +100. Similar caps these days aren't so easy to find, and impossible in kits. The majority of what's available today are +/-20% and many of the newer caps made for power supplies have extremely low ESR. The circuit was originally designed with higher ESR values which may cause problems with the low-ESR caps... or may not. I think C6 may sensitive in this circuit, but I only looked at the circuit for 30 seconds... and too much for my tired brain right now. I'd suggest checking the original cap values (C and ESR) and tolerances then use common sense to find something similar that's in stock. You don't want to get the same capacitance only to find it's in spec at -15% when the original was +50% and then find you're getting lower output. Sticking with the power supply caps isn't a bad idea but don't gravitate toward the low-ESR variety. At least that's what guides me when refreshing a supply.

In this PSU’s circuit there isn’t a single electrolytic capacitor that wouldn’t benefit from lower ESR. I have recapped many switching PSUs in the last 10 years including Apple II ones and I always put electrolytic capacitors with low ESR and a higher voltage rating. Not a single one of them has broken yet.

Regarding the tolerance – when you recap just buy a few extra ones and measure them with your multimeter. Even though modern ones are rated as +/- 20%, most of them are actually within 5% and I've seen many that are within 1%. Just put the more accurate ones and that’s it!

I did finally get round to removing all the output-side electrolytics for re-capping, see photo of the nearly bare board. I measured the values of all the old caps and every single one of them was about 50% high. So the 1000uF caps were 1500uF, and the 220uF caps were 330uF, etc.

The ESR of the output caps doesn't seem too bad. The original smaller 220uF caps were about 250 mΩ, and the original larger 1000uF caps were about 60 mΩ. Someone with more experience can comment if this seems out-of-spec. The new replacement caps are generally lower ESR.

I am measuring out-of-circuit with a pretty good LCR meter, so these values are very accurate. The meter is a BK precision 880 LCR with Kelvin clips.

I do have all the new components to re-assemble the PSU, but unfortunately I must have incorrectly measured the length of one of the axial caps, and the new one is too long and doesn't quite fit right. So I have to reorder that cap. The big power transistor 2N6543 had to be purchased from eBay, and the pieces I received seem to test okay.

Bare board

This is expected. As I already mentioned in post #9 just above, the electrolyte of old capacitors dries up and they increase their capacitance. This happens even to the best brands, like the Nippon Chemi-Con bellow from my Apple IIe's PSU:

20221120_203909.jpg

The increased capacitance is not a problem, since they are mostly filter capacitors. However as the capacitance goes up, their breakdown voltage goes down and they become a problem if their voltage rating wasn’t high enough from their operating voltage to begin with.

If the new axial capacitor is too long, you can just put it standing up or at a 45 degree angle. It’s not going to affect its operation in any way.

I wouldn't even mess with axials this day and age unless you absolutely have to. They are getting harder to find from reputable manufacturers, and are usually only general use 85c caps. I prefer 105c, even if it won't get near that. Should extend their lifetime. I haven't ran across an axial that I haven't been able to replace with a radial.

Sometimes you have to get creative with bending the leads to make them lay flat. And sometimes a pea sized blob of hot glue is needed to hold them in place. In maybe less than 10 cases I had to use solid wire to extend a cap lead. But they are all replaceable with radial.

Digikey seemed to have a reasonable selection of axials. In this case, the original cap was a 10uF @ 15V. I repalced it with a new axial that is 10uF @ 60V, and with a much lower ESR. The temperature rating for the new cap was 105 C (brand was Vishay/Sprague), so I think it's a quality replacement. The larger electrolytics are all Panasonic brand caps, also with 105C rating @ 5000 hours.

I guess normally I would have just bent the leads to make the bigger cap fit, but this since this is the original PSU out of a rev 0 Apple II, I'm just being more picky than usual.

Below is the the recapped PSU (minus the fuse), with the other blown components (Q3 transistor & resistors & diodes) replaced with new ones, ready to go. I'm pretty confident that it's going to run, since I individually tested every component (most out-of-circuit). But I do have a couple of 60W 120V halogen bulbs that I'll put in series when I fire up the PSU for the first time to limit the current.

Recapped PSU

I am not sure this is such a good idea. The Apple II with only the 16K language card uses around 20W, so if you put two 60W bulbs in series (which is equivalent to one 30W bulb), the PSU will only get around 72V (480Ω to 720Ω voltage divider). I am not so sure this will be good for the Apple II. These calculations are for purely resistive loads for simplicity, but they are not too far from the real values.

Correct, no way in hell am I connecting the Apple II rev 0 mainboard to this thing yet. Plan is to put a DC load on the various output power rails to gradually bring them up to full power.

Once I am convinced that the PSU is stable, then I will begin work on the rev 0 mainboard. Which, after 30+ years in a closet , is almost certainly not going to work perfectly on the first try. But the board and all the chips seem to be in perfect condition, so we'll see.

It's a thing of beauty. Every chip (including the RAM and ROMs) is dated early 78 or 77. Only thing that could make it better would the light-green slots...

Rev 0 Mainboard

I don't think you should plug-in this PSU to this Rev.0 until you have tested it on another much less valuable motherboard from an Apple IIe or Apple II+. Otherwise you could really damage the memory, no mather how much you think you have tested it on the bench. Same with the the Rev.0 motherboard - use another working PSU from Apple II+ or Apple IIe to get it going. Only then you can try them together.

It's a switching power supply - it will either work, or not.

With a small load on the outputs if you get the desired voltage I'm pretty confident that it will be fine in your Apple II.

The only voltage adjust you have it the +5V. All the other voltages are +/- 10% or so. If they're not bang on -5, -12 or +12V don't be alarmed.

I totally understand why you would want to be much more careful with an Apple II that is worth a few grand, as opposed to an Apple IIe worth a couple of hundred bucks.

Or you might understand that the original caps were rated for -10/100... and most used in the II supplies were around +60% when new. The OP is seeing is exactly what you would expect from these caps. Not because all 4 caps aged equally, but because they are designed for use in power supplies where +100% is a benefit. I didn't go into the whole description of why the originals came from the factory at +60% is a good thing, but in this application these caps are just banking power on both the primary and secondary side. As I mentioned, the more common currently available caps with +/-20% tolerance are a concern for two reasons: first because they tend to be in the -15/+5% range which first doesn't give the same extra capacitance the originals provided. Second, anything greater than -10% is below the original spec so the power supply will be underpowered on those lines. How much below depends on the capacitance value for rail and a greater problem for the lower power lines (-12V and -5V).

@deltamind106, a couple comments about your new caps, I would have gone with new caps with simiar capacitance to the originals, so an 1000uF original that was 1600uF I would have selected replacements in the same range knowing a +/-20% wil be within original spec. There is only one electrolytic cap on that board where capacitance is timinging and that's in the switching path. I tried to guess before, but I didn't spend any time deep diving because I really wasn't interested (sorry). As to your ESR comments... some may say BK Precision is not as "accurate" as you suggest, I've personally seem more varitaiton in their products than others. In addition, every lab I've been around, the techs avoid BK at all costs. YMMV. As to the values, the current low ESR caps are in 10's of mΩ and the originals were much higher even though still below a couple hundred mΩ. My main concern is with that cap resposible for switching, too low can be problematic because swithing frequency is sensitive to ERS. I think someone working on the Sony PS used in the SCHD found the same when recapping and had to select an alternate with higher ESR. ESR can be a factor, despite what others here say. I also see you've already installed the new caps, did you measure them first? I'm curious how they compare with the originals.

Well I don't know, I guess I've had good enough results with this BK Precision 880 LCR meter. The only point I was trying to make when I made the comment about my LCR meter was that it's not a $10 special from China. I'm sure there are nicer and more accurate LCR meters out there, but I do believe that this LCR meter is good enough for the purpose of measuring the components in this PSU.

I did measure all the new caps before I put them in. All were right around the nominal value give or take a few percent. The ESRs were all lower, some significantly lower, and others only slightly lower than the originals.

You mention that one of the capacitors is critical for timing the switching frequency. This makes sense given that there must be an oscillator circuit on the high-voltage side. But which capacitor is it? I would guess C6 or C9? I understand that in an RC oscillator circuit the ESR of the capacitor may play into the design of the RC values, and therefore may affect the switching frequency. I really wish this PSU used a controller chip, as my analog circuit analysis is by no means expert level.

Based on my initial testing of the PSU, the switching frequency is about 10k Hz. See photo below of the waveform from the output-side transformer pin (before the diode) that generates the 12V rail. The scope capture was taken during initial start-up when the voltage on the output is ramping up from 0 to 12v. That's why the duty cycle of the square wave is well above 50% and also why the voltage is gradually increasing over the 10 cycles shown.

Switching Frequency

Then why is it that I have never seen a single one that is under the rated capacitance? I have done a lot a recapping in the last 10 years on electronics from the 70s, 80s, 90s and early 2000s and every single one of them has been over. Even now I've got boxes of old caps and not a single one is under. How is that statistically possible? Not only that, but the amount by which their capacitance is over has always corresponded to the capacitor's age.

Are you saying that a modern 1000 uF capacitor that measures with a multimeter to be 995 uF is out of spec and therefore should not be used to replace an old 1000 uF ???

Also I don't know where you get your new electrolytic capacitors from, but as I mentioned before most of the ones I get are actually +/- 5% when measured, even though they are rated +/- 20%. But even is you are getting ones that are usually -15%/+5%, what is stopping you from measuring them and just using the ones that are within -5%/+5% ?

Are you suggesting that he should have replaced all the 1000 uF capacitors with new 1600 uF ones??? If you are, this is totally wrong and no one does that. The spec is for 1000 uF and you try to get as close as possible to that value as you can.

Are you a CE or EE? If so, your education in physics, manufacturing, and electrical engineering answers that question. It basically comes down to dumb luck you've got all caps that are above rated values. In some applications greater capacitance is just as bad as lower values. In a swith mode power supply... most of the caps do just fine with higher capacitance because that just means there's more power avaliable for the load. Caps manufactured today have a very high level of consistancy, and the desire is always to just be "in spec" there's no rule that it needs to be above the rated value, just that it needs to be within the tolerance. Almost all caps in a single lot will have values that are very, verly close to all the others in that lot. That said, it's not always the case and why all caps should be checked before using, always the case. What you seem to be missing is that the caps which were originally used in switching power supplies are spec'd for -10%/+100% because of how they are used. Designed tolerances are often +/- 10% for all components and engineers work design around those worst cases. In caps + and - can both be bad but it depends on the application, again in a switching power supply most just bank power and banking extra power is not a problem. Caps resist changes in voltage and why they're called "filters" is because they keep the voltage more stable that the source. But to maintain the voltage they need to shed power when the source level drops or the load demand increases.... the capacitance determines how much power they have available for load demands. Most caps on the II's power supplies had a tolerance of +100% and often came in at +60% which is exactly as the designers expect. The margin below is -10% for a good reason, because if great than -10% the result is LESS output power available to the load. When one line goes low the system becomes unstable, and that's never good.

The change in capacitance change is not just a result of the age, there are several other factors so what you said is not correct. Even something as simple as humidity can have a big impact, I wouldn't expect caps in devices stored in non-climate controlled places in the desert, to be anywhere close to those stored in favorable climates. There's a lot

If I don't know exactly what I'm looking for I'll ask my mfg reps and get their suggestions, they know their products better than anyone. I'll get samples which are checked to confirm they match my needs. I'll then go to the same sources you likley use but instead of filtering through the thousands of options on digikey, newark, mouser, etc. I search for the part I need and go with it. I did check some of the kits, hoping they were hand picked by someone with similar knowledge, but was disappointed by the results most went into the bin for other progects. Again, a "good" cap within spec of -20/+20 that's anywhere in the -20 to -10% range is out of apple's spec and would be a problem.

No not a blanket statement like that, but yes match best to the original design spec and if know, the original values. So yes if the caps are banking power, if the originals measure 1600uF then replace with 1600uF instead of the 1000uF unless you can find a 1000uF at -10/+100% becauses these will likley mirror the originals. Most important, I believe we agree it's better to replace the >30 y.o. originals than roll the dice with the caps originally designed with a 10 year shelf life and couple thousand hours of use. Every manfuacturer will say using 30 year old caps is a bad idea. This isn't because they will be bad, but reliabliity comes into question and the proabilibilty they are reliably stable is fairly low in the long term. I frequently say a "working" power supply doesn't always mean a "good" supply. For the repalcemets I check the BOM tollerances and compare against the original caps. With enough samples you get a pretty good idea what's good. I understand the engineering and the design. Would I suggest someone that isn't and EE/CE doing this? Probabily not, because wihtout the education one can't determine a good match, and it's simple to accidently make things worse with bad replacements.

I don't really have the time or interest to argue with you and there is really no need, since anyone can see the many fallacies in your arguments.

My advice to deltamind106 or anyone else considering recapping is not to listen to your advice, but instead use new capacitors that match the original capacitance written on the old capacitor or in the schematics as close as possible and always measure them. Luckily he has already done all that correctly.