I’ve got an Apple II with a duodrive, and I can’t get a recently purchases system floppy to slide into the master drive. The problem is mechanical and only affects the master drive, not the slave drive. Sadly, though I can get the system floppy into the slave drive, as far as I can tell, you can’t boot the machine off the slave drive.

I think at least the master drive is otherwise functional, because some older floppies that I have go in fine, and can be read. The older floppies are “Datalife” brand and “Elephant Memory” brand (or something like that). The system floppy is new, acquired online, unknown brand.

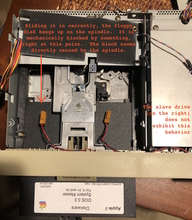

I’ve attached some pictures to explain the weirdness:

1. If I put the system disk in “correctly”, it hangs up on the spindle. From marks on the floppy housing, it appears the hang-up is right at the center of front edge of the floppy (i.e. not on the second edge, the back edge of the window that shows the disk). This floppy is no different in thickness from my older floppies.

2. Double checking if something about the housing material matters, I put the floppy in “sideways” (see image). When I do that, it slides in all the way, no problem.

I suppose that one way to fix this is to go buy another, different system disk and pray it comes with a different (thinner??) housing. But even if successful, this would not solve whatever is the root of this problem.

Has anyone had this experience?

Some added details: the interior of this computer and disk drive are very clean. I think these never saw much use. I see no rust. The plastic spindle piece (not seen in photos) is wobbly and spins freely. The "wobbly" behavior seems correct (it allows the spindle to adjust to and mate with the central hole in the disk). The gap between the spindle components seems adequate, and the gap seems the same on the Slave drive and Master drive, yet the Master drive blocks the system disk at the spindle.

I've had some no name generic bulk floppies that I bought maybe 2-3 years ago that occasionally seem to get stuck roughly in the same spot. On both my duo disk and my IIc internal drive. It's usually the same disks that has issues in both drives. Other disks from the batch never seem to hang. But I never bothered to investigate where the hang occurs.

I think it's just low quality/poor quality control on some of these generic bulk floppies that were probably produced at the end of the double density drive era, and corners were cut. I never encountered these issues back in the day using name brand floppies made at the time.

Usually I'm able to get them in after 2-3 tries sort of very lightly tweaking the disk as I insert it.

Diskette jacket too wide and getting caught on a burr in the plastic slides maybe?

Drive door not opening fully?

The pressure pad hanging down a bit too much?

If it is physically hitting something it bears investigation as to WHAT it is hitting to make it stop.

Is the pressure pad the wobbly spinning circular part that I'm calling the spindle, or is it something above the read/write head?

The front of the diskette doesn't get much past the "spindle" thing, and nothing else even comes close to the diskette on its way to becoming fully seated. It is certainly hitting something physically - if I push really hard a little ding forms at the front edge of the floppy diskette housing. But when I look into the drive, including with a bright headlamp on, I don't see anything in the way.

I'll see if I can get the vendor of that floppy disk to put the system onto one of my older floppies, which goes in without a problem.

thanks

I think he means the pressure pad is the felt pad opposite the read/write head that sits on the top of the floppy media to press it against the R/W head. It's literally a pad. The part you are taking about is the idler spindle.

It's certainly not the pressure pad: as you can see from my first photo in the OP, I can't get the diskette past the idler spindle.

All I can think of now, is to get the DOS 3.3 system disk copied onto one of my older floppies. Would anyone here be able or willing to do this for me? I would send you my old floppy and the system floppy in a self-addressed and stamped envelope - you could keep the system floppy. I'll select one of my older floppies with contents that I won't mind losing. I already sent a message to the vendor that sold me the DOS system floppy, asking them for this kind of help, but they've not replied.

Thanks for considering it!

Boris

I think you are going about this the wrong way.

Something is blocking the path of the diskette.

Something is wrong with the disk drive, not the diskette, so why try to solve the problem by using "older" diskettes. At some point the drive will deteriorate to a point where nothing will go in.

Logically, you should investigate further, find the fault and correct it.

Path-to-failure is exponential, not linear, so it will be a very short time before nothing goes in.

I agree with baldrick, and I would like to figure out what is blocking the diskette. Towards that end, I had done tests as described above:

1. I put in an older diskette - it goes in with little difficulty... so I suspected something about the newer floppy diskette, maybe thickness??

2. I put in the newer diskette sideways - it goes in with no difficulty. This suggests that the "window/aperture" to the media is somehow involved. But for the life of me, I can't figure out a mechanical reason/cause, how the window might have anything to do with it.

Looking into the two drive mechanisms, I can see no difference: both the master and the slave drive show the same clearance between the idler spindle. Unfortunately, the way these things are build, I can find no way to observe what actually happens mechanically at that point, when I slide the diskette into the mechanism (even with the cover off, as shown in the pictures above).

For now, I would be happy to have the DOS 3.3. system on one of my older floppies that I know will go into the drive; just so I can further test functionality of the drive and also the slave drive.

thanks

I don't have any special insight to the mechanical layout of these drives, but the things I would try, since you can see a large part of the mech uncovered, would be to push the partially inserted diskette either up or down from different sides to see if it makes any difference in clearing a possible obstruction, and to use an inspection mirror with a bright light to look into the diskette-spindle interface from the sides. There are other possible techniques to find where it could be sticking (it looks like the front edge might not even be the location of the interference: the pictures show the diskette's central hole is even with the front locking lever?) by, for example, wrapping a smooth surface such as an address label around the leading edge of the diskette and using a contact indicator like blue layout fluid to see at which point it touches something.

Thanks for those great ideas. I'll pursue them. In the meantime, the vendor of my new DOS 3.3 diskette that has this problem, has offered to copy the DOS 3.3 onto one of my older floppies. So I'll have that to fall-back on.

I have had drives where the bottom hub either sits up too high or the metal has swollen and it catches some hub rings on the disks like that.

A possible workaround since only the drive 1 chassis seems to have the issue, and 99% of the time you are most likely only using drive 1, physically swap the two drive chassis in the duo disk. It's been a while since I had my duo open, but pretty sure the chassis for both drive 1 and 2 were identical when I tore my duo down to deep clean it.

@ Robespierre many thanks again for the tips!

I inspected the issue using a small mirror, actively looking at what happens as the floppy is slid into the drive, and indeed this clearly showed the mechanical problem. I also would like to point this out to Apple (only 40 years too late!): there is a mechanical engineering design flaw at fault here!

A 5.25 floppy diskette has two little notches cut out, straddling the centerline of the leading edge. I don't know what they are for, but these are what caused my floppy to hang-up with the leading edge of the floppy just a little past the centerline of the spindle. As these notches travel over the sharp inside edge of the bowl shaped, hard metallic lower spindle, the inside corner of these cutouts can catch just a little bit on that sharp inside edge of the "bowl." Furthermore, as the floppy is pushed past this point of resistance, the forces on the floppy tend to push that little cutout corner down, causing even more friction. So when a floppy starts to hang even just a little bit at this point, the likely outcome is that with repeated insertions, the inside corner of those little leading edge cutouts will start to get deformed downwards, and this only worsens the problem. In the case of this brand new system floppy I had gotten, the sleeve/case of it must have been just a teensy bit thicker than standard, so it caught right away, deforming right away, and becoming quite impossible to insert further. The fix was laughably easy: I simply used my fingernails (thumb and index finger) to pinch down that corner of the cutouts in the leading edge, and the floppy went in smooth as silk.

In another topic I'll ask a question about what happened next!

duodrive-floppy-hangup.jpg

Nice work! I have also noticed those notches, but never learned just what they were for. In principle they do make it possible to design a drive that only allows diskettes to be inserted forwards (and not backwards or sideways) by having a gate that requires the notches to unlock it. I am not sure that any drive was actually made that worked that way. Another possible function would be to act as a "keyway" to permit the diskette to be inserted all the way to the back, to restrict the heads from loading if the disk was inserted the wrong way. I did notice that cardboard transport protectors had the same notches, as if they were required to allow the heads to load.

FYI, those are called "relief notches".

Because the flexible disk jacket is folded, the creased edge is stiffer than the rest of the jacket...sometimes too stiff. In the event there's any stress or pressure on the disk jacket, those relief notches give it a place to flex without bending at the access hole.

There are some relevant diagrams on this playfully-named Twitter account called Relief Notch. ("It's a stressful job but someone's got to do it!")

Don't forget to check the DuoDisk cable (DB-25 to DB-19) for clean contacts and good mechanical connections at the disk controller and the DuoDisk.

Most of the upper spindle mechanisms are hung on a spring which may have deformed over time.

The fix is fairly simple - you have to raise the upper spindle - either by modifying that spring or causing the drive mechanism to open a bit more.