Hello Community,

I need your help with an Apple II powersupply that I repaired and that re-died one more time.

The power supply is a ASTEC A11040B.

The first time, I changed the 2 RIFA Caps on C1 & C23. A few days after, It stop working with no reason,

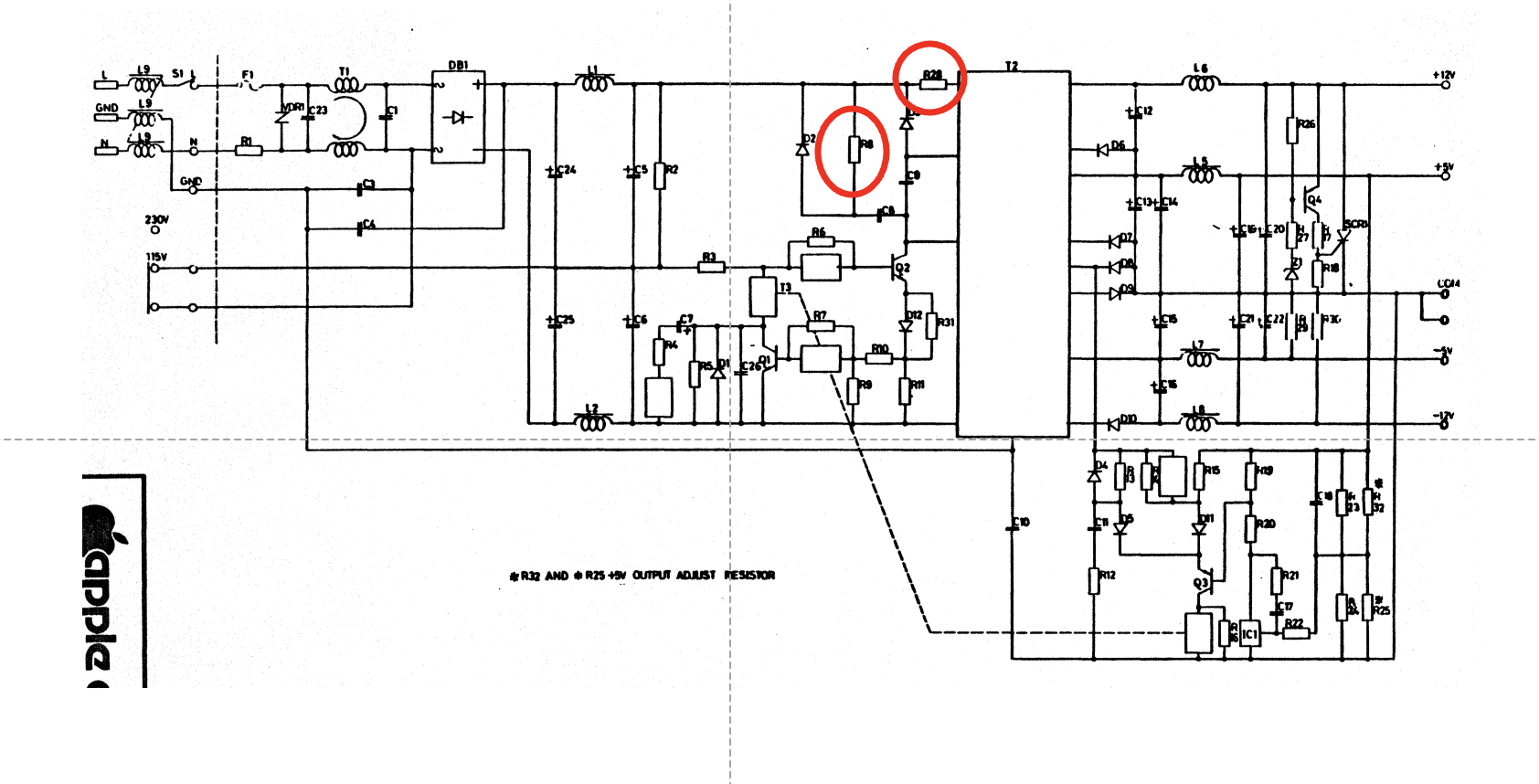

I discovered that R8 & R28 are dead, I decided to replace them, I put power back and the 2 new resistor burn with small fire.

It is completly out my skillset and I want to understand what to do, what ot check, and if possible to repair it

In red the 2 resistors burnt, in green what I have already changed

In a nutshell, I need a wizard to help me on this.

Vincent

Hi Vincent,

check Q2 for shorts, also check C8 for shorts.

The schematic is not complete, because the arrangement of windings inside T2 is not shown: it must be inferred from the schematic for AA11040 (no B). By doing this, you will see that there is a winding from R28 to the collector of Q2. Since R28 is a 1 Ω, it must pass 1 A of current to heat 1 W; to burn it must pass over 2 A. This only is possible if the Q2 is shorted or stuck in conduction.

R8 is a 120 Ω, so it must have a voltage over 12 V across it to heat 1 W. This could happen if Q2 and C8 are shorted.

It would be a good idea to measure the values of all resistors on the primary side if you find any that have burned. Testing them in-circuit will not tell their true resistance, but will indicate if any are open or shorted. Also please consider safety: only touch the primary side after disconnecting the power cord for at least 15 seconds. There are bleed resistors R2, R3 on the primary reservoir C5, C6, C24, C25, but relying on them to prevent electric shock is not the best idea—you can manually discharge the reservoirs by touching a 5 kΩ resistor between L1 and L2.

Hello Robespierre,

It seems that I have a short on Q2 between the base and the collector, using a Ohmmeter very clear.

I will check as well the rectifier diode on the primary and use a light as well to avoid burning new stuff.

With what can i replace the Q2 which is a 2SC1875 ?

Thnaks

Vincent

Not knowing the polarity of Q2, it could also be a condition related to R3 or R6 causing it to conduct hard-on.

Also, the rectifier could be blown or shorted. There is 115 volts on the other side of it...so probably shorted or off spec?

It is these issues with old power suplies that always makes me comment "buy a universal power supply replacement kit from ReActive Micro"

https://digitroncorp.com/Digitron/media/Files/Datasheets/2SC1875.pdf

The Q2 polarity is fairly clear to see that it is a PNP, when zoomed in on the PNG file and comparing it to other transistor symbols on the schematic.

Hello Robespierre,

I have unmount Q2, and it seems not to be shorted...

C8 is not shorted but showing strange value 1nf instead of 47pF

I am a bit lost, because I have also checked the diode on the primary and all are working...

R2 & R3 are dead as R8 & R28

DId you check the bridge rectifier out of circuit? I've had several of those power supplies fail because of a shorted bridge rectifier.

Hello Prometheus,

Not yet and how do you test it ? should I desolder it ? I guess I test it like the classic 4 diode bridge ?

So I have un solder the DB1 Diode bridge and it is seems to be ok,

1 diode left to be tested and I unsolder the D3 to test it and it is failing, it is letting the current in both direction.

Screenshot 2024-09-12 at 06.41.27.png

So far R3, R8, R28 are burnt and D3 is a dead as well,

Would the failure of D3 explain all my troubles ?

Thanks

Vincent

I highly recommend getting an LCR-TC2: https://www.aliexpress.com/item/1005002488012717.html

(The LCR-TC3 is out as well, but I haven't tried it.)

I have one, and I am using it

In this case unsolder it and test it 2 pins at a time. You should see 4 diodes with nearly identical parameters. I also recommend testing every single component on the switching side (the ones to the left of the transformer T2).

This is where I am,

Screenshot 2024-09-12 at 14.23.13.png

One more of countless victims of recapping stupid fashion.

Well as always thanks retro_devices for your kind comment ;),

so In the end, the gulty was D3, replacing the R8,R2,R3,R28 and C8 & C9, the powersupply is alive again

Vincent

I'm late to the game, but something which stood out to me is your replacment for C7.

Normally the wrapper has some clear indication of the cathode, but I don't see that in yours. Is that a polarized cap?

The more important thing in this case for moving forward is what voltage rating did you use for C7? The original is 10V but long-standing position was that was actually too low and a 16V (or even 25V) should be used.

Hello Jeff,

I replaced the C7 by the exact same one 10V and polarized, I was not aware of increasing the voltage to 16V or 25V, I need to check if I have these

Vincent

But why would you recommend installing a new off-shore built power supply with unknown quality components that will likely only last a fraction of the lifetime of a repaired factory power supply? The factory power supplies in many cases have been running for over 40 years. I'm quite certain the replacement power supply will only live for a fraction of that.

I often use a 25V 105c low-esr polarized electrolitic in this application.

I can't answer for baldrick, but can say this... the RM system is not some crappy off-shore device built with "unknown" quality components. If you've checked the site, you know he's got a level of knowledge above many and isn't looking to make things based strictly on profit.

The other thing is, and this this is all still my thinking.... this is really no place the average user/hobbiest should be messing around. I totally agree the AA11040B is an beutifully simple design which does work extremely well. It's history is solid and it's durablity is proof of how well it was made. The problme tho, is people. Really, in all honesty, the people who should be doing these reworks are people with training in the related fields. The ones who can read the schematics, have training in rework, and have skills way above the hobbiest. The reason I say this is because these are power devices and things can easily go wrong. Somone who cannot select the parts themselves from a distributor should not be touching these boards. To encourage the average person to work on these is really irresponsible. Can the average person do this? Of course any human can learn to solder and youtube makes it look super easy! But knowing how to solder is just the tip of the iceberg. Far too easy to damage a board/sysstem when clueless and proof of this litters the Internet. So rather than have joe-hobbiest start reworking thier power supply it's often best to KISS (keep it simple stupid) and encourage them to instead go buy a plug-n-play replacement from a reputable dealer (ReactiveMicro) instead of working on the power supply.

I have experience with the manufacturer that builds the power supply that RM uses. Henry did select the best power supply from what was available to him, but to have any power supply manufacturer design and build a power supply today with components of quality equal to what was used in the Aztec supply, would place the cost of manufacturing far above what would be an attractive sale price for the marketplace.

Having considerable experience in both specifying and servicing switching power supplies, I will stand by my earlier statement.

First, I don't disagree I'm 100% in agreement the ASTEC supply is a tank. A simple and effective design built very well. I also agree it's very hard to find anything at any price today which can be considrered an equal. I too have expeirence with SMPS, but mine is on the design side so we have similar undesrstandings but also very different perspectives.

Are we talking about the same RM product? I'm talking about the Universal Supply kit. If that's the same, why do you say: "Henry did select the best supply from what was available to him"? It's an in-house design created by Henry. Of course it's the best he can source because it's his creation!

For better (smd ecaps) or worse (many other components) we can't source the same parts which were available 30-40 years ago. We gotta made due with what we got now some are better today, but some are worse.

So, if someone doesn't konw what they're doing their best option would be to find someone who can correctly source good (not cap kit) replacements to keep the original supply (provided it's not a Dynacomp suppy) as it was designed. If the first option isn't taken, the second best option would be the RM given it's a custom design for exactly the purpose its being used. The option that should be avoided at all costs are the crappy ali-babba supplies. Nothing but crap inside.

But the vendor contracted to build it has limitations in their component suppliers, not to mention the over all reduction in quality of modern components in general.

I'll keep repairing and re-building.