Hi all. I have an issue with an Color Composite IIe monitor, model A2M6021 that I was hoping someone on the forum could help me with.

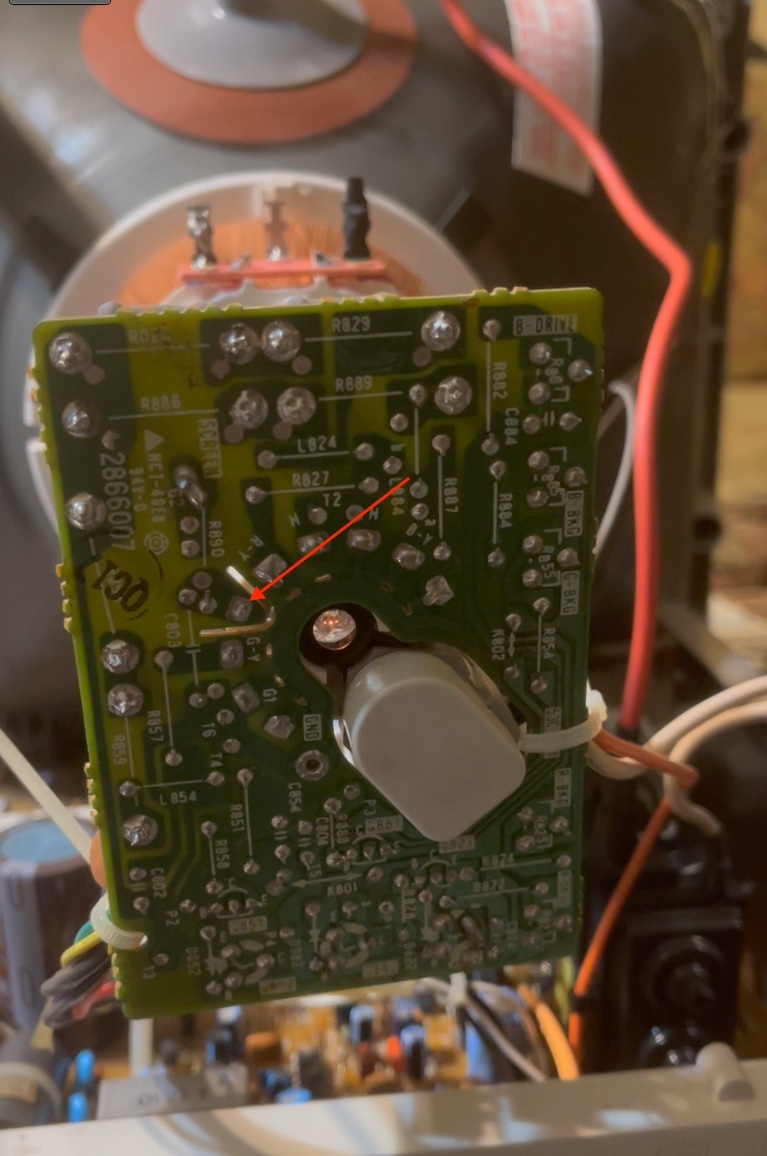

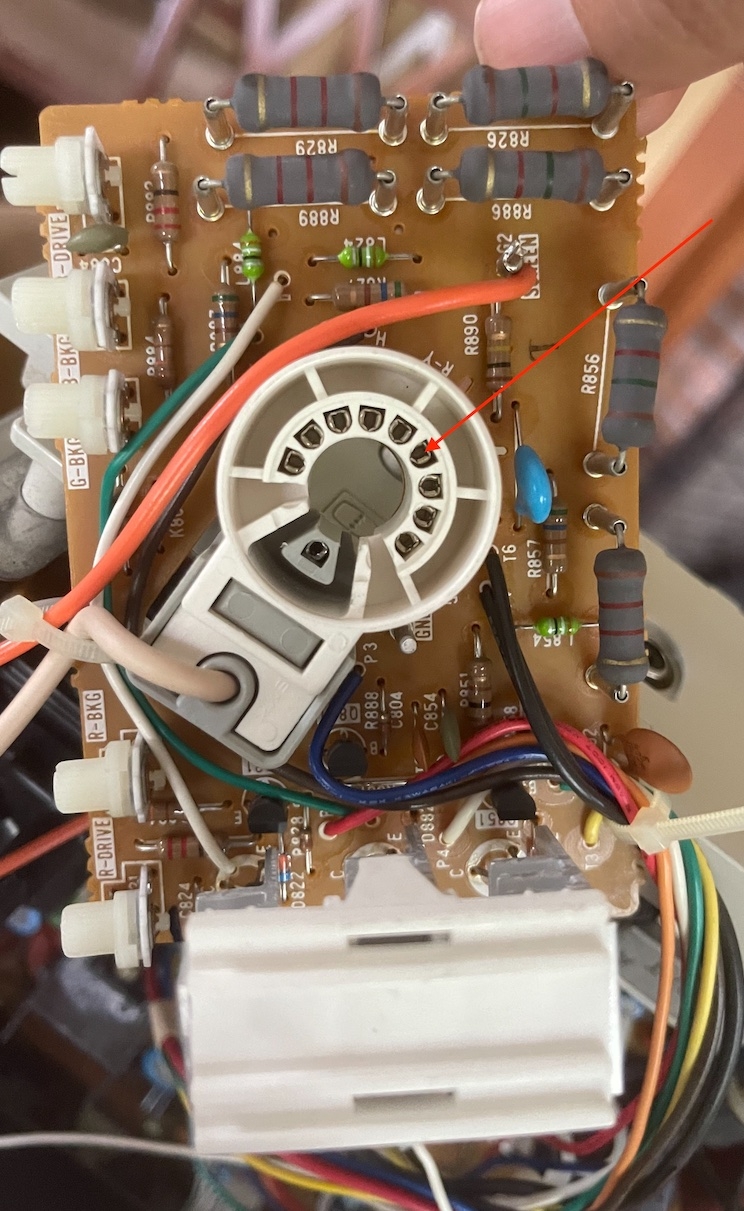

I have had the monitor for about three years now. Has worked flawlessly with my IIe since then. Recently, it started to develop a high voltage arcing issue. I would hear an occasional snapping sound, see a flash on the screen, and smell an acrid odor coming from the back of the monitor. After opening up the monitor, giving the surfaces a good dusting using anti-static brushes and compressed air, I was able to find the source of the arcing. It is located at a particular pin of the tube socket on the CRT neck board. I will attempt to post a few photgraphs of the area.

I am not familiar enough with troubleshooting monitors to know where to begin with this. I was considering desoldering and then resoldering that pin, to see if the solder joint might be the issue. But I thought I would try getting some advice before proceeding. I was able to download the Apple Services Procedures manual from the Internet Archive, which has some information but has no wiring schematics or reference voltages I can use to do testing. I am flying blind here, and hope that someone on the forum can point me in any useful direction.

Thanks in advance!

What is this V-shaped thing on the board exactly where the arc is forming?

The V-shaped thing is a cutout through the circuit board itself.

Oh, I see. To me initially it looked like a piece of wire on the board. :)

Yes, resoldering should fix the arcing.

Yes, the image was a bit deceptive. But thank you for the advice! Will resolder tonight and fire her up again. Cross fingers ...

The arc is coming from the G2 (SCREEN) electrode. It may be caused by a loose connection to the neck board, but could also be a sign of excessively high voltage at the SCREEN or FOCUS grids discharging through a spark gap. A high voltage probe would allow these voltages to be measured.

Thanks robespierre. I do have a B+K HV-44A high voltage probe that I use to discharge the CRT at the anode. It has a voltage meter that reads up to 40k. How would I test the volgage at the SCREEN and FOCUS grids, and what values should I be expecting?

If you put the - clip of the HV probe on the clip that touches the gray outer CRT coating (called the "dag"), and the + side on the screen or focus pins on the CRT socket (the G2/screen is the one with the cutout, supplied by the red wire from the flyback, and the focus is the white wire from the flyback that goes directly into the "bump" of the socket), the G2 should be roughly 200–600 VDC, and the focus roughly 4–8 kVDC. The exact voltages are listed in data books based on the CRT tube number, which I don't know.

The design of the socket may make it hard to reach the focus anode (at its high voltage it looks like special measures were taken to cover and shield it). Also make sure you wear rubber gloves when measuring operating CRTs, and don't bring your hands any closer than necessary.

That cutout is quite intentional. It creates an air-gap spark arrestor to protect the screen grid circuits and the CRT itself from an over voltage.

Thanks to all for your responses. After much troubleshooting, including resoldering of components on the neck board, and swapping out both boards with ones I knew to be working, I determined that the arcing was coming from inside the CRT tube itself. Confirmed by a black scorch mark along the neck of the tube that was visible when I removed the yoke assembly.

I tried replacing the CRT tube using an A2M6021 that I bought on the cheap. This monitor was not powering on and was advertised as "not working - parts only." I found that the fuse on the main board was blown. After replacing the fuse, the monitor powered on. No more arcing! And, I got a picture and could make out the text of the Bitsy Bye program launcher (connected it to an Apple IIe).

But ...

The picture was "wavy" and distorted, mostly horizontally. Nothing I did with the rear knob vertical and horizontal sync adjustments worked to stabilize the picture. I tried swapping the main board, the neck board, and the yoke assembly, and adjusting the horizontal and vertical pots on the main board but the output remained the same: an unstable picture. I also tried replacing the degaussing cable, which seemed to be loosely connected to the main board, with another cable that connected correctly. No dice. I tried using a degaussing tool on the screen. No luck.

What are the chances that trying yet another CRT tube might yield a stable picture? Is it possible that an unstable picture like that could be caused by a defect in the CRT tube itself? Is there anything else anyone can think of that I should be trying short of searching for a replacement tube?

Thanks in advance.

The "unstable" picture has nothing to do with the cathode ray tube itself, as the geometry is solely externally controlled through the yokes and the deflection circuitry on the circuit boards. The only things besides a short (which in some cases can be fixed using CRT rejuvenators) that fails in a tube are

Collapse of the picture along any axis is a deflection problem, external to the CRT. If the picture judders, check the horizontal sync circuitry.

Does this "wavy distortion" change when you press the manual degauss button?

That makes sense, thank you for the explanation. There is no manual degaussing feature on this monitor other than turning the power on, and that makes no difference. I have a degaussing wand too. Using that made no difference either.

The reason I am stumped is that I swapped out the mainboard, neckboard, and the yoke assembly (I ... have a lot of spare parts lying around), just in case the problem was being caused by me having accidentally zapped an IC with static. But still, the picture remained exactly the same -- wavy and distorted horizontally, and no knob adjustment fixes the problem. And the weird thing is that the picture is identically distorted no matter how I swap out the circuity. It is almost as if it has been adjusted somehow to be distorted by default.

I fiddled with the internal horizontal and vertical pots on main board but turning them did not seem to change the image at all.

Very strange.

The reason I asked about the degauss button (usually it is present on higher-end color sets) is that as long as the degauss circuit is active, "wavy distortion" is exactly what you would see in the picture. The degauss coil carries 60 Hz current directly from the AC inlet and uses it to create a 60 Hz varying magnetic field around the tube face. The circuit is designed so that when it is working properly, the amplitude of this oscillating field gradually tapers off until it is nearly zero. However, if the degauss button is held in, or the circuit fails to taper off the field, the oscillation will continue and the picture will constantly be "rippling" from the varying magnetic field. So if holding in the degauss button results in no change, it means that the degauss circuit was effectively "stuck on" and is the cause of the distortion. Indeed this may be the reason the degauss coil was disconnected before you received the set!

However, when you said you had used an external degaussing coil, I am struck that perhaps there is some misunderstanding. Degaussing means "removing residual magnetization" and is required for color displays (only!) because the aperture grille or shadow mask is ferromagnetic. A residual magnetism on this structure causes color purity problems (green which should be red, blue that should be green). Slight magnetism, such as that caused by moving the monitor around or using it nearby other equipment, is erased by the built-in degauss coil. External degaussing coils are primarily not for use with CRTs but for tape transports. They are only needed for CRTs showing serious color problems after exposure to very strong magnets such as the ones in large dynamic speakers. This strong magnetization doesn't simply happen to the CRT during normal use, storage, or movement. Erasing it correctly is also not simple since the degausser's varying magnetic field must be slowly moved away from the tube until it is over 6 feet away before being shut off. Any kind of residual magnetism only causes static changes to the color displayed in part of the screen. Your symptom of wavy distortion cannot be caused by it.

Robespierre - Your explanation made sense, and I was convinced that the CRT tube could not be at fault. I replaced the main circuit board with another I had laying around and ... voila ... waviness gone! No more arcing and a steady picture. I am planning on testing the other main board to see what component failed. Probably an IC in the stabilization circuitry?

The only thing left to troubleshoot is that the displayed text has a slight "shadow" -- looks like a red shadow. During my troubleshooting efforts, I replaced the yoke assembly with onc from a different monitor, and as a result am using a different convergence ring. I will replace that with the convergence ring that came with the now-confirmed-to-be-working tube, and see if that helps.

Thanks for your analysis and explanations. If only I could find the circuitry diagrams for this model I would feel like I am flying less blind here.

For doing geometry alignment on CRTs it really helps to have a good source of test patterns. But if you connect it to an Apple II and run a program to fill the entire screen with the letter "E" or "M" that can be a good start.

For "colored shadows", the first thing is to determine if it is a purity or convergence issue. Convergence is the relative angle of the three electron beams (red, green, blue): this angle is controlled magnetically by the so-called "convergence rings" which are in front of the yoke, and electronically by a "HSTAT" and "VSTAT" circuit, and sometimes also by dynamic convergence circuitry for tighter control over the full screen area. If the angle is not correct for the shadow mask, then thin white lines such as "E" will have a red cast on one side and a blue cast on the opposite side. So for a vertical convergence error, the top bar of the "E" may appear red and the bottom bar blue, or vice versa; for horizontal convergence error, the left bar of an "M" may appear red, and the right bar blue, or vice versa.

Purity on the other hand is not an electronic circuit, but is the result of magnetic effects pulling electrons slightly off course and making them spiral in to the screen at a slightly deviated angle. This means the electron beam will pass through the wrong hole in the shadow mask and illuminate the wrong color phosphor. The way this is corrected is by using "purity magnets" which are small square ferrite magnets glued or taped onto certain positions around the tube neck. The magnets cancel the magnetic field within the tube neck as far as possible so that there will be no force making the electrons spiral. If while displaying a white test pattern, you see a red patch with no corresponding blue on the other side, it indicates a purity issue (and the same for other colors). To adjust the magnets you need to break the glue that holds them in position and rotate them slightly while viewing a test pattern.

Thanks for the advice. I was able to fix the text shadowing issue by replacing the conversion rings with the ones that were originally on the neck of the CRT tube I am now using. So it was a convergence issue. Everything is working perfectly now.

Appreciate all your help with this!