Hi all,

I've been experimenting with a toner transfer and Toner Reactive Foil (TRF) for remarking chips on my Apple 1 build - namely the MMI proms.

I believe that I can refine my process a little further, but here are my results to date (these proms are some old ones off other hardware that I used to practice the technique).

The basic process is as follows :

- Clean the target MMI proms, removing all original markings

- Produce the artwork

- Print it at correct scale in reverse onto toner transfer paper

- Transfer the toner to the chip

- Place the TRF foil over the toner and fuse it

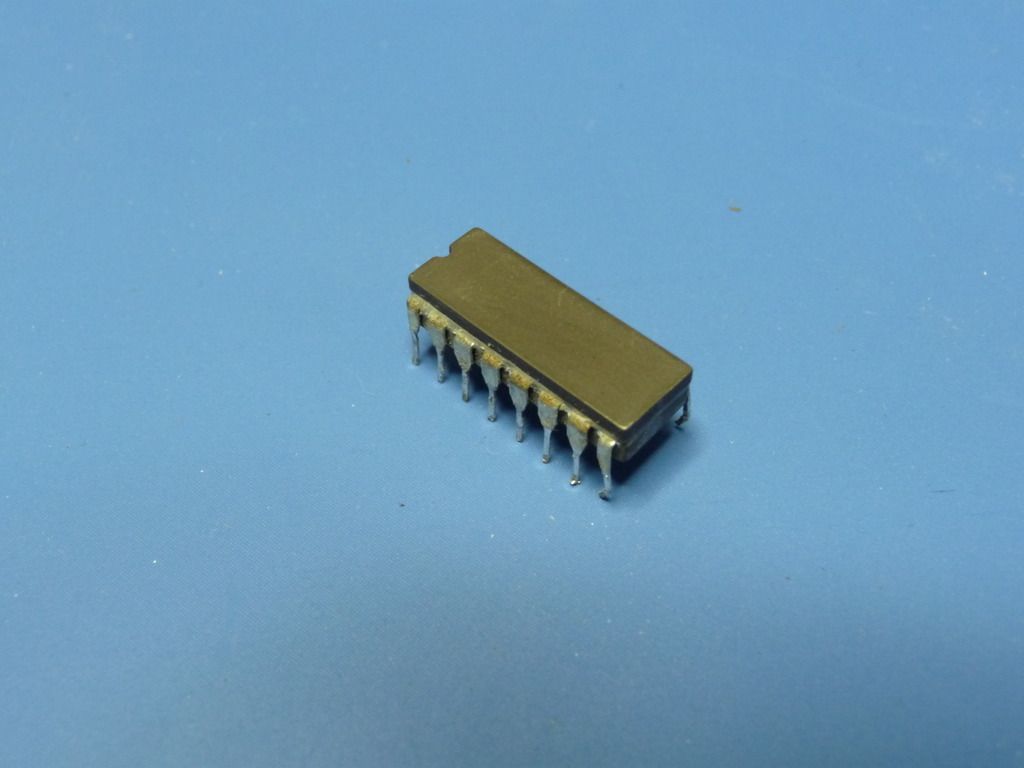

Clean(ish) chip :

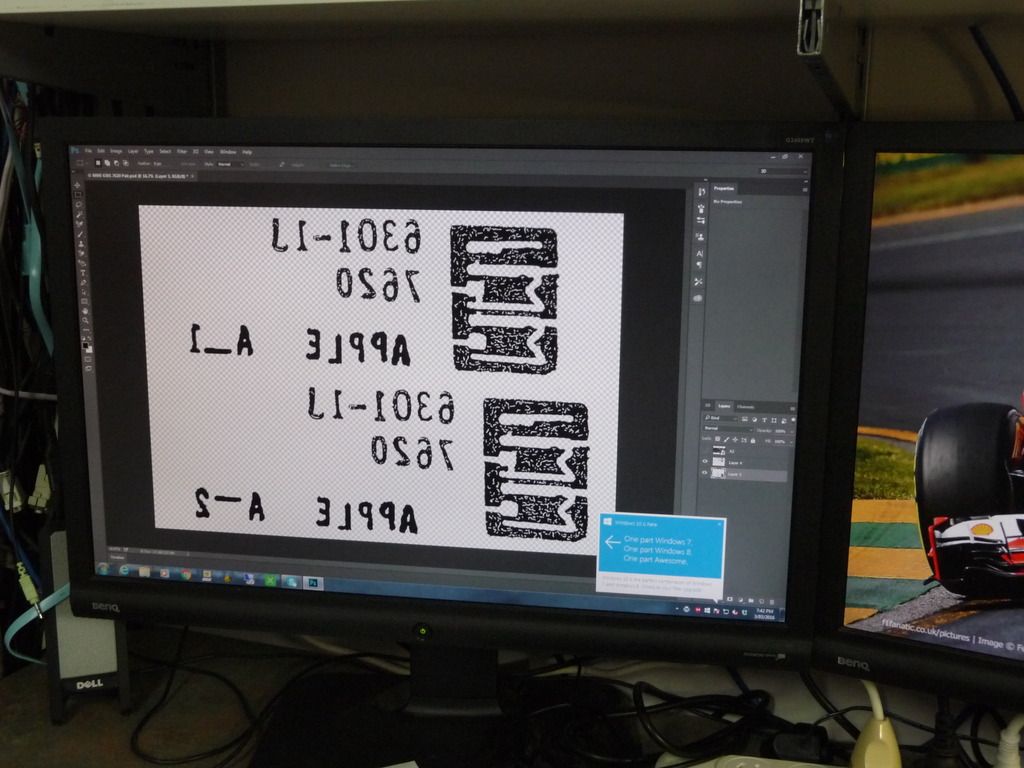

The artwork :

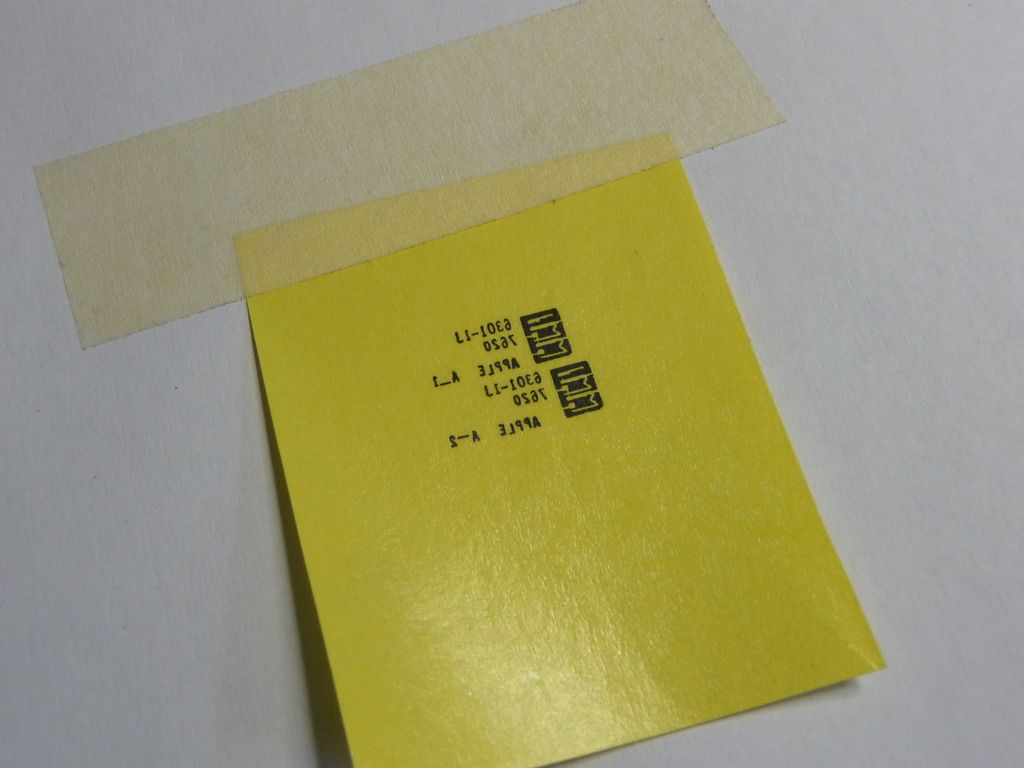

Printed to transfer paper :

Toner Transferred to chip:

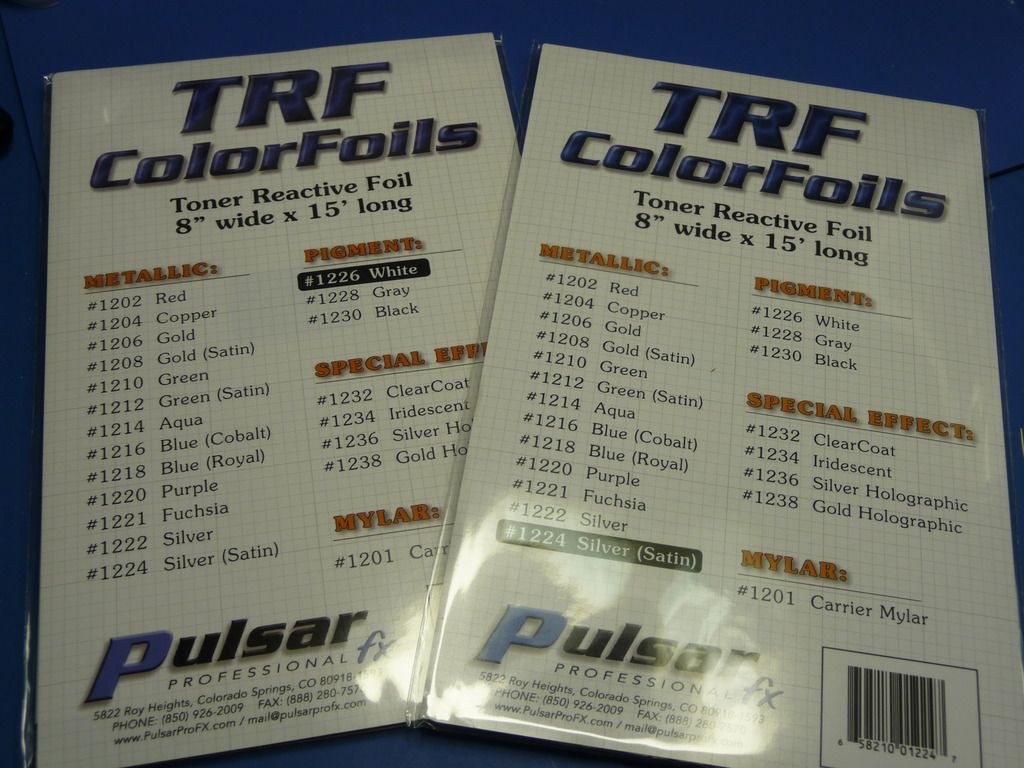

The TRF foils used (Silver Satin and White)

Job done :

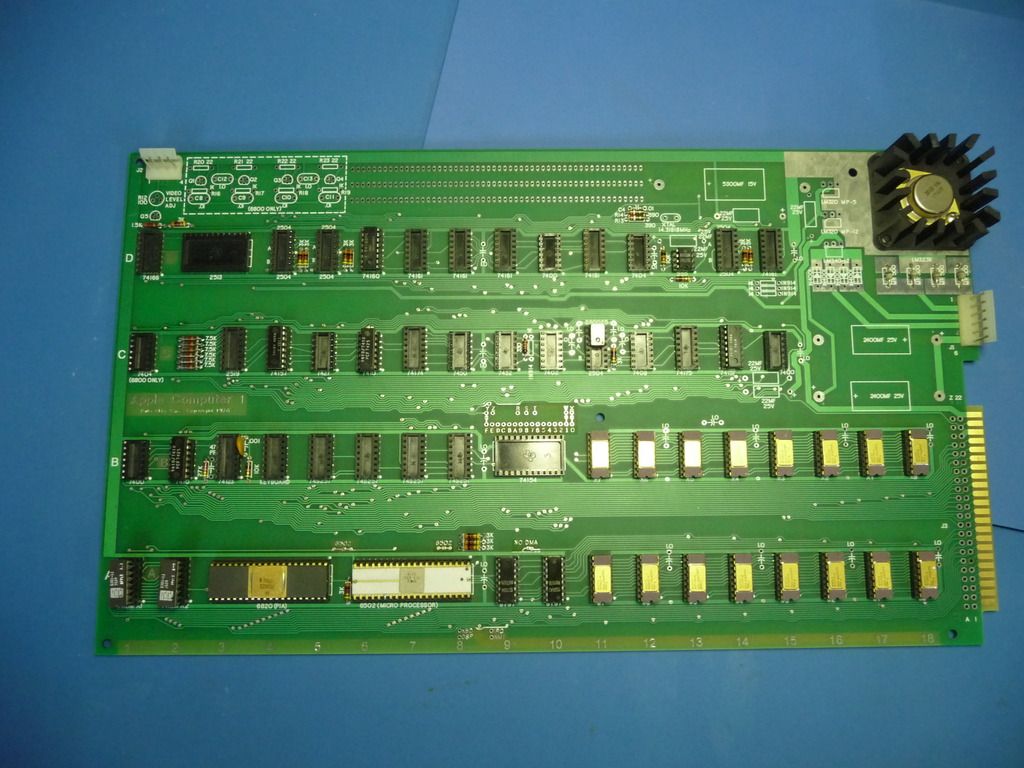

Sitting on a board :

My artwork will be further refined and the process further tweaked, but I think I'm getting somewhere.

What do you think?

The current markings are a little bright compared with an original - it's more the silver satin than the white though. Its hard to see in the photos, but the silver satin is actually a metallic just like the original painted markings were. The limited color range in TRF foils is the issue (ideally a dark silver satin would be a better choice, but not available), but I've been chatting to the folks that make the TRF and they made a few suggestions including use of steel wool to age the logo.

I'll give that a go and see if I can tone it down a little that way.

I may also experiment with their DecalFX process, in which you end up with a dry rub on decal.

I'm not trying to spit out fake PROM's here - my board is after all a replica, and I would like to make the PROM's look as good as possible. The PROM's that I have are later datec odes, and the MMI logo changed some time in the late 70's so I wanted to retain the original MMI logo on my PROM's, plus the Apple stamps - may as well just do the lot including the date code.

In fact since it is just a replica I may possibly use the process to re-date other components on my board - I think the dry rub decal may work well for capacitor dates on the 5300uF and 2400uF caps. Of course the originals will look better, so where possible I'm trying to obtain components with the correct dates to start with.

So, after carefully working it with 0000 steel wool :

Interestingly I found that you really need to do this, as the TRF application covers more of the toner than it should - ripping it back a little reveals more of the original logo (as per the artwork) plus ages it.

Whilst they are still a little brighter than original PROMS, I'm happy to stop here and call it done

These PROMS are practice ones - now I have to do it for real on my actual PROM's.

Why are you faking the chip markings? This doesn't seem like a great idea...

I'd say it's for the same reason that people are making "fake" Apple-1 computers.

Its a replica Apple 1 and I'm replicating the chip markings because you can't buy (or at least I haven't found any yet) MMI 6301-1J PROM chips that are :

a). Blank and ready to be programmed, AND

b). Have the MMI logo of the era (logo has changed on later chips at least a couple of times), AND

c). Have APPLE stamps on them.

Since I'm replicating everything else I may as well do the date code as well

I posted this thread as I thought it would be a good thing to share my technique with others who may be able to use it to do the same, plus I was hoping to get some feedback as to whether people felt that they looked good enough to use on a Apple 1 replica. If anyone has any questions about the process, I'd be happy to help.

Hello Dean,

don´t get irritated by such postings..... it´s normal in a forum not to get each time

a relpy like expected.....At the other hand sharing experiences should at the long hand

be the real purpose of the board..... by that thanks for the contribution....

in such cases you could just even also reply: why do you perform rafting or why do you ride a bicycle ???

I´d just remind that Corey986 published a similar posting about "treating" a LM323K for the

Apple-1:

http://www.applefritter.com/?q=content/recreating-gold-lm323k-apple-1

and like you will recognize, in that thread there haven´t been such replies......

I have made some similar experiences with obvious replies in some threads and don´t mind about them,

because finally after a couple of years that contributions are valued for what they are:

sharing experience or sharing documentation..... and those who join as newbies the

topic ... welll they in general are thankfull for finding information that helps avoiding

mistakes or get inspired for similar tasks....

nice job done !

sincerely

speedyG

Thanks speedyG

I do hope that others find this info useful. I just had a look at Corey's thread, and he used the same process. The cheap eBay toner transfer paper is pretty good stuff - that might be better to use for the LM323K's as well.

I have yet to try this on a plastic IC package - be interesting to see if it works.

Dean

I did use toner transfer.

And in the end I did find a couple of real gold LM323k a few years later and replaced the relogo'd regulator.

BTW: This same argument about "fake" vs "reproduction" goes around in the car community as well.

My opinion, If I recreate a 1955 Porsche, it's a reproduction. Unless I try to pass it off as real, then it's a fake. If I take a 2015 Skoda and rebadge it as a VW, then it's fake.

Sorry guys. A "reproduction" is a FAKE. You can twist the words and the explanation however you want, but you will just damage your own market for such items.

The only reason to do this is make someone else (or yourself) believe you own something that you don't. The fact that it is "not available" any more is no excuse. Someone, somewhere owns real ones and you just made what they own worth less.

Once someone sees they can sell these items for a high price, someone will get ripped off. Even if YOU don't try to pass it off as real, someone else will and you can't control that.

Hello Peter,

if we would hijack the thread to start debatte about the legal side of this i´d start up with the movie

"Catch me if you can" with Tom Hanks and Leonardo di Caprio and the story behind that movie.....

then maybe we´ll screw up with the statement that at least 30% to 35 % of the art presented in Museums

are fakes..... no idea where we will get if we screw that up till the debatte will get philosophic....

Just for example: If Rochester electronics buys the rights of an outdated IC and initiates a reproduction run

and labels them same like the former original IC´s ( they have the legal right to do that because they paid

for the entire rights )..... what do you call that ? "legal fake" ? It´s still the same IC from the same or

similar mask .... but it´s made from present nowadays material.... and it´s manufactured by a company the owns

the legal rights....

or what´s about a guy who makes out of flintstone an arrowhead like a native 400 years ago....

the stone is the same age and same material and if he does not use modern tools it´s the same

"manufacturing process"....what about if the guy then trows the arrowhead away ?

and what about the guy who finds the arrowhead and puts it in his collection.....

not to start thinking about the guy to make expertise and just can date the arrowhead by the date of the stone ????

and just remember about another thing: some companies permitted their customers to make backups from their

original software disks and even added for that pupose 1 or 2 original labels from the company with their

legal sold disks .... and not each time that labels indicated the disk to be backup or copy.....

But i would not argue about the crime.... you will find crime in nearly any kind of "market" on "ancient" things....

otherwise we would be forced to talk about the junkyards in China that "relabeled" crap from the junkyard

and resold that crap passing markets in Hong Kong and forcing manufacturers to create specific "research

and trace" departments at the entrypoint of their manufacturing rows to detect and sort out that kind of crap

and causing of course the need to spend huge amounts of money ( or causing in other words huge damage )

to protect own production from that kind crap.

I´d just better leave at this point.... LOL

just my 5 cents....

speedyG

and just to complete sarcasm:

Oh ... Oh..... maybe now i will get trouble next time i want to visit my fathers graveyard in the U.S.

and Homeland Security will sort me out at the border before entering the USA for this kind of academic thoughts ?

:ebc:

That's a bunch of different scenarios, but basically this thread is specifically about marking chips in a way to be intentionally deceptive. Yes, other people do it- companies do it, and it's not OK and should not be encouraged.

I think anyone that considers themselves a collector (and actually, that is not me- I am just a casual user) should frown upon this.

Hello Peter,

i didn´t want to hijack it by that topic....

i just wanted to display different points of view....

even among collectors ( and i believe i can count me along with that group ) there are

different opinions on that topic.... but like i also mentioned - it would

take far to much space to analyze and get down to the basics....

i do respect your opinion !

But like often in real life - some like it black/white

and some also try to view also "the shades of grey" between...

i´d even agree that in rather many cases at the end there will be fraud detected

because you often can´t judge at the beginning what will turn out to be the result...

but just in this very case:

altering the datecode on a functional chip i´d guess no trouble for private replication

if that unit is never sold....

but adding the Apple codes is seriously a violation of copyright law.... at least the moment the unit is sold !

so far i´d agree

speedyG

Nicely done! You'd make a good prop builder.

I'm with Corey on this - if you try to pass it off as the real deal, then it's a fake. If it's seen for what it is, then it's just a reproduction and shouldn't devalue the real item.

I can see now why many are putting their own makers marks on the underside of reproduction products though

Every replica component I have done in the past has a maker mark that identifies it as not original. This is a big deal for me. When I was doing my PROMs for the Mimeo with my press, I marked the back of the chips.

BTW: These same techniques can be used to repair chips as well. I fixed a friend's white 6502 which had a worn logo by scanning mine and printing a new logo on to the chip. Don't know his original date code, but it had to be close since it was the same package. So is that a fake because maybe his chip date was 7650 and mine was 7652? I have no way of knowing what his original date was...

Hello Corey,

like i explained in the previous posting: the borders are a bit foggy at the legal side...

there re also debattes among lawyers and judges, what may be called "repair", or "restoration", or

"reproduction" or "fake"....

if it´s signature / sign from originating factory it will be rather more judged to be one of

both first options.....

but if signature /sign is originating from other factory or copyright it will rather more be treated

like one of the two last options....

at least it seems to be clear definition at legal side: if some action joins together with

action of "betrayal" - then its judged by legals rather clear as "fake".

Just to spot out how difficult this topic can get: How would you put down the limiting border,

if someone is restoring a picture - and in that task is doing "artwork" at the signature of the artist ?

That is the reason that every task of restoration shall be documented well and documentation shall

remain with the item.

speedyG

Did a full set of PROM's including ACI (Apple Cassette Interface) proms :

Again used steel wool to age them a little. These were originally Signetics 82S129 PROMS - it was very time consuming to remove the original markings. I had to lap them on a stone, then wet sand them to get the top flat and clean. The rest of the transfer process was ok - I tweaked my artwork and added the ACI proms to it.

Side by side with the real deal you would be able to see a colour difference in the silver, but on their own in your replica board they look pretty good IMHO.

DeanClaxton, they look great! When "Replicating" something, the only way to have a replica is to make it look LIKE the real thing!

When I build models of WWII ships, I try to make them look EXACTLY like the real thing, even though their scale makes it obvious they are not. In this case, it's YOUR replica. If anyone was to buy one thiniking it was real, Corey would end up doing the authentication anyway and he'd tell the difference

I see this as building a replica, not devaluing the real thing.

Excellent job!

Zan

Thanks Zan,

I'm happy with the process. I've verified the prom contents before and after (using an adapter I put together to allow reading of the Proms in a standard EPROM programmer) and all good. I did make up a simple jig to ground all chip pins whilst working on them.

Corey would have no trouble at all spotting them as replica's but I think they will still put a nice touch on a Mimeo or Newton

I'm working on the artwork for a pre-NTI set at present.

Dean

Well - i would not go that far to claim Corey as the final "expertise authority"

even if he is one of the most well known experts on this topic ( as far as i know ).....

just to explain how difficult that problem is, about what is called to be "fake"

i´d explain another point a step more ahead that i just made a shot at with the prvious posting

when aiming for the "shades of grey":

Rembrandt - one of the most well known artists of the netherlands - had a studio with dozends of students....

it´s well known at the experts that at most of his paintings have not been performed completely by himself....

he passed huge portions of that what you might call "boring details" of artwork to his students and

a lot of his pintings have been "manufactured" by his students up to 70 % of the entire painting....

some experts even guess that at some paintings only his signature has been made by himself !

These paintings are presented in famous museums today and have been sold for millions of dollars....

Does a painting from a student just become to an "original Rembrandt" just resulting from a original

signature ?

And resulting from this question the next one:

Does a Dollar bill just become an original from the original signature of the director of the ministry

of finance and every buck manufactured therafter from a printing press is a fake ( because it does not bear the "original signature" ? LOL

i just turn back to the opinion i explained previously....

the problem is at legal side the "rework of the marking by the Apple trademark/marking".....

it´s recommended to at least mark that chips at the bottomside as "reproduction copy"

to prevent abuse later by any kind of sale....

but the chips themselves at least look "quite alike" close to the previous original chips.

speedyG

I also wouldn't claim to be the final authority on this also. As time goes on the reproductions will get better and we will have to get better at spotting them.

As for these specific chips, I actually would not have a hard job spotting them. I think with the technique used, a simple drop of ISP would disolve the markings. ISP does not do that to originals. They also won't "feel" right when you rub your finger over the top of the chip. I can't explain it, but you can feel the difference if you have one for comparison.

I'm working on my classes about replicas and restorations for VCF East. I realized one major difference in a reproduction and the real thing (even between byte shop and NTI boards for that matter) is the way the board flexes. I can feel the difference between both a Mimeo and Newton. And of course the real ones. Blind fold me, but let me hold the board for a minute and I can tell you what's an original one. I don't think that feeling will be easy to replicate, but it is hard to document. I suppose if I sent a board to a materials science lab they could asssign numbers to this whole process and a way to measure it.

On a final note, I do agree with having markings underneath to indicate it's a reproduction. Anytime I do a reproduction part I make an obvious to an expert mark somewhere so that there is no way to pass it off as original.

Cheers,

Corey

Hello Corey,

just short explenation to your statement:

The basic material of the PCB´s in former days has been "softer/weaker"

so it was more easy to bend that material.

PCB material got by the more modern years "more stiff" because of the change of the fibers

and the glue in that PCB´s.

speedyG

I'm not sure this would be helpful to those who want to print atop of IC's, but I used to work for a company that specialized in IC printing equipment. (I was one of several engineers working for the company) The printers used what was called an "offset" print process, whereas the actual print came from a gravure (etched) plate OR a plate that was made (daily) from a process using a Photopolymer material on a backing plate. (There's one for sale on eBay, Item 251581887069, but I'd never consider buying one because the source materials for photopolymer plate making are no longer available) Making photopolymer plates took about an hour from start to finish, so they'd make a months worth of plates ahead of time. Gravure plates took much less time, as they were made using a high power laser that cut into a coated aluminum "print plate".

Depending upon the type of plate you used would would define how you would print.

Gravure plates used an inking system that basically sponged ink into the gravure, and a blade would sheer the ink from the plate. (leaving the gravure pattern inked) Then a silicon pad that would "lift" the ink out of the gravure pattern and apply it to the IC.

The process was timed so that the surface of the ink was partially dried so that the silicone pad would lift it and apply without smearing.

Photopolymer plates were easier in that an inked roller would (basically) roll over the (convexly) embossed plate, then another roller would roll over the inked photopolymer plate and apply it to the IC.

About the inks: These were UV cure white inks. The inks were blended (much like a 2-part epoxy mix) but wouldn't cure until they were exposed to strong UV light. The ink itself was roughly the consistency of 0w5 grade motor oil. (reference only folks!)

Today, if you really want to make a permanent print on an IC and you were doing a quantity of them, I would approach it this way:

Get a rubber stamp made using an artwork you supply from a computer file such as a scaled bitmap or whatever. Office suppliers still make rubber stamps for folks that want "return address" stamps.

If you could get one of the self-inking models that hasn't been inked, this might be a possible solution. But cleaning the ink out after using it would be a trick.

Once you get the stamp, buy a roller similar to this one on ebay: Item 272137529517 [Edit] Get 2 rollers because you have to ink the face of the rubber stamp.

Make a sliding guide rail for the IC so that it will slide under the silicone roller with light contact. (you should be able to make this using an IC packing tube) mount the roller so that it can be adjustable as you slide the IC under it. It should be able to lightly turn the roller as the IC is guided underneath. Last thing to do is rig up your rubber stamp so that it can apply the inked surface to the roller evenly and consistently. You can do this by making a pendulum mount above the roller. If you can picture this, you've basically made a 1-off IC printer that will make fairly consistent prints for cheap $. (pending quality of your apparatus)

The trick from here is the ink. I've not experimented with those new commercially available "clear" UV inks that they're advertising on TV as of late, but it looks like an interesting concept. If you can get some very finely ground iron oxide dye, (the main ingredient in white inks of this type) you might be able to make up a batch of your own. Just don't do it in sunlight.

For clean-up of the chip and rollers, use paper towels & Acetone. Uncured ink removes easily. (though it can be quite messy)

Good luck to those who dare ...

The process macnoyd is describing is a form of pad printing. I have made a rubber stamp for the "APPLE -Ax" part of the image. I have found that it is extremely hard to get a good transfer with a rubber stamp because of the small size of the lettering. It might be easier to etch a copper plate using the laser toner method used to make PCBs and use a silicon pad to make the transfer from the etching to a chip package.

regards,

Mike Willegal

Thanks macnoyd - nice writeup. I suppose one could align the surface of the chip and the surface of the stamp such that they were co-planer and aligned centrally along their length, and then space them at an exact measurement from one another equal to a multiple of diameters (1 or more) of the roller (obviously with some wiggle room and perhaps 2 positions since the original MMI stamps were all over the place), and then you could use a guide to ensure the roller tracks parallel to the stamp and chip. Applying the paint to the stamp may be tricky (stamp it into paint then drop in the jig, or apply the paint directly to the stamp?) - then just (carefully) roll the roller along and job done - the transfer anyway. Then pop it under UV for a bit.

The stamp would have to be made in reverse to a normal stamp since there is a double transfer (stamp to roller, roller to chip).

I do have a UV EPROM eraser - may work to harden the UV paints. I'd have to muck around a lot with paint colours to get the silver right, but at least I could get the exact colour match that way. The white would be another stamp again (multiple stamps).

For now I'll likely stick with the process I have, though it is not as hard wearing as paint it is at least very flexible with artwork and for a replica should be fine.

Quick note: my comment about Corey was a joke, hence the emoticon.

emoticon.

Please continue!!

Zan