While taking a short break from troubleshooting my NewtonByte Prototype board, I've successfully completed the assembly of UncleBernie’s new Gen2 improved ACI board following the provided instructions. I didn't opt for the wave soldering look, keeping it all gold. I also used the blue 104 instead of the brown ceramic disc capacitors to keep more of an NTI look. It will keep me from bending it too.

Installing the SMD was pretty easy following the tricks in the instruction guide. I put one solder point down. Then with a set of non-magnetic tweezers, I held the SMD down and melted the first solder to it. Then I added a small solder on the other side. Soldering on the SMD was easier than I thought it would be, but I had to use my head band mounted magnifying (jeweler type) glasses with double lenses. :-D

The instructions were easy to follow and provided highly detailed steps, along with useful tips and techniques for assembling and soldering the components onto the board.

I've also tested the ACI by loading BASIC, 30th Anniversary Demo and more. It was a great surprise to see that the LED actually works as intended. At first, it didn't work because the volume on the iPod was too high, as required to use with my other ACI boards, where the LED doesn't even light up. For this reason alone the Gen2 is worth it.

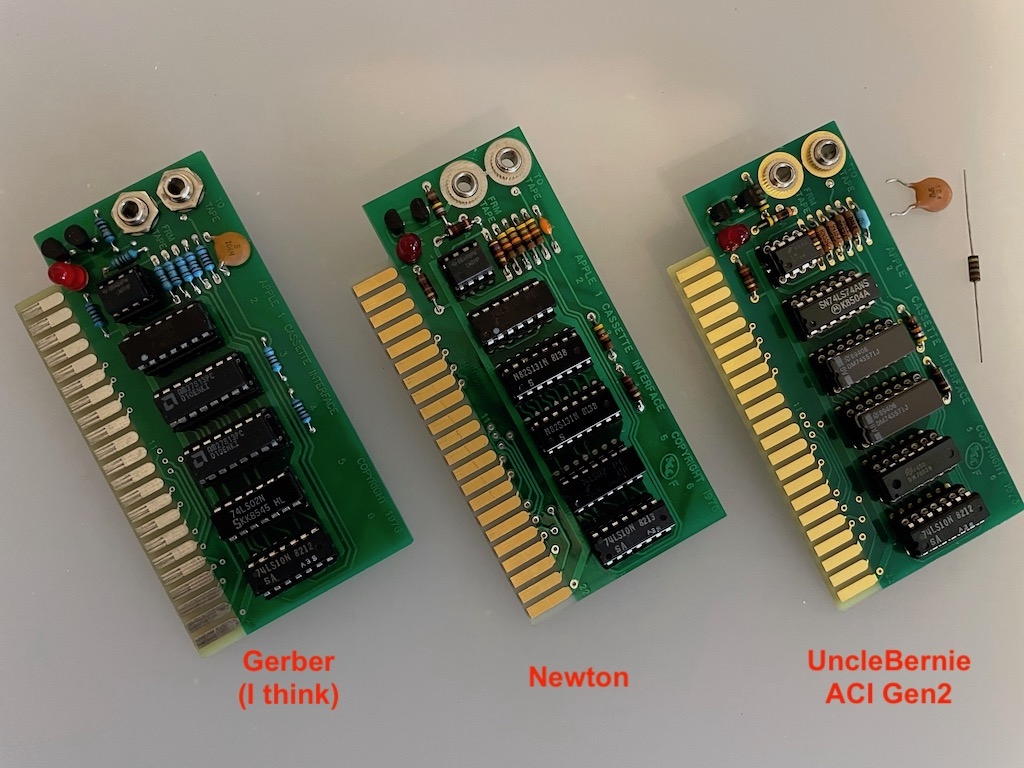

But, I also love the quality and color of the Gen2 ACI boards compared to my other ACI boards. The Gen2 is actually a little heavier and feels better made just holding it in my hands.

It looks great!

I think I agree with you about wave soldering, it's a waste of time and money. If you want to achieve the best possible resemblance to the original ACI just fill all visible transition holes with solder. And use a 3mm LED, not a 5mm like yours.

I'm a bit surprised that dear Uncle Bernie's board was the heaviest, the pseudo-gold plating and SMD capacitor hardly make the difference. I also have the same set of ACI cards, and the heaviest is the variant of Mike Newton because of the honest thickness of 1,8mm instead of 1,6mm of JLCPCB. Plus Mike's boards have a texture that you can clearly see in your photo, something JLCPCB unfortunately can't offer. Their boards are always smooth.

In terms of user friendliness here the respected Uncle Bernie has no competitors, the LED performs its function perfectly and loading programs does not cause such problems as the original design.

1976 Apple-1 Cassette Interface.jpg

Thank you Macintosh_nik, your ACI board looks great too. Anything Apple-1 is a bit like a piece of art. The only issue I've seen with my non-gold connectors, is they seem to wear or scratch a bit quicker and therefore I try not to remove it too often. (see the photo on my first post)

The weight difference is small, possibly due to the PCB and using machined sockets (not the SMDs hidden under the socket) on UncleBernie's Gen2 Improved ACI compared to using pressed sockets on my other builds. To me the Gen2 feels better made or more exclusive. Also after testing it for the few days, I've had better results loading programs with the Gen2 compared to my other ACI boards when using an iPod or the Panasonic Cassette Player.

The LED brightness being consistent and reliable not just barely flickering (using with the cassette player and ipod), makes it easier to set the correct volume using the LED brightness to load programs. Also I know the 3mm LED is more authentic, but I prefer the darker red vintage look and larger size of the 5mm LED.

The other ACI boards work well too, but tend to have a higher failing rate when load programs, primarily due to the sensitivity of finding the right volume setting at first it seems.

In post #2, Macintosh_nik wrote:

"... Newton because of the honest thickness of 1,8mm instead of 1,6mm of JLCPCB."

Uncle Bernie comments:

I ordered the 1.6mm thickness on purpose, because it plugs and unplugs smoother. Having chamfered edges also is a useful option to put less stress on the 44 pin slot connector. It has been my experience that 1.8mm thick PCBs require much more force to insert and remove, and on the long run this ruins the 44 pin connector. I had one of them (early new old stock, one of my first Apple-1 builds) cracking due to that stress, and despite I have a professional desoldering station (electrical vacuum pump and a special "solder sucking" soldering iron with a hollow tip) it was a lot of work to replace the connector. For any hobbyist out there without such a desoldering station it is absolutely hopeless to replace the connector without damage to the motherboard.

For this reason I highly recommend the use of 1.6mm thickness PCBs for daughter cards.

The "recipe" for these ACI PCBs at JLCPCB is: 1.6mm base material, double copper weight, double ENIG thickness, chamfered edge connector.

The double ENIG thickness adds some hefty $$$ to the bill but it improves the "looks" of the golden edge connector over the normal ENIG process. Now you got maybe 10 atom layers of gold instead of only 5 . . . but it looks a little bit more yellowish. No match for the real PCI bus industry standard gold fingers not offered by JLCPCB. But having the "real" gold fingers is manual work which even in China drives up the costs per PCB considerably. This is one reason why the "Newton" PCBs are so expensive compared to the cheap offerings. Full electrical test is another cost driver.

The much better readback reliability of the Gen2 inproved ACI was studied independently, see here:

https://github.com/flowenol/ACItest

https://github.com/flowenol/ACItest#example-test-results

So it's not only a myth or subjective experience from builders. The explanation why the original circuit is so much worse in terms of readback reliability is too involved to be done here, but from the 1% spec of the 10k resistors for the LM311 comparator's input biasing network and the excessive hysteresis designed into the original circuit are circumstantial evidence that Woz really was struggling with making it work. I also have a hunch that he did use a different comparator at first, and later switched to the LM311. This is because the LM311 does not require a negative power supply voltage, even in the original circuit, but other comparators of the time do, and in the original ACI, the negative supply voltage on the bus is used. In the improved ACIs (both Gen1 and Gen2) the negative supply voltage is NOT used, I run the LM311 between +5V and 0V, so these ACIs also work in the Briel Replica-1.

The improvement of the readback reliability does NOT come from the added components. Actually, I could have taken components away from the original circuit, and could have replaced one resistor with a capacitor, to get the same improvement. But this would have disturbed the original "looks", which I wanted to preserve. I also did not use foul tricks like having disconnected components around just for the "looks". So additional components were needed. SMDs were chosen to be able to "hide" them under the sockets, again, to preserve the original looks. Equivalent components with leads did exist in the mid 1970s, so it's not even "cheating".

I think that most likely, it was the poor readback reliability of the original ACI which brought about the "buyback" decision, and this conjecture is supported by testimony of important early Apple-1 owners like Lisa Loop. According to her story (she ran a place where kids could learn programming in BASIC), the Apple-1 crashed from time to time, which required a reload of the BASIC interpreter, and according to her, this failed all too often, frustrating the kids.

Was the original ACI a botched P.O.S. ?

IMHO, no. Actually the modulation method Woz chose and the way he compensates for the time distortions from the large hysteresis is quite brilliant for the time. It was the fastest cassette interface (for unmodified, music, cassette recorders) back then, with ~1500 bits per second. The same modulation method and (almost) the same code worked fine in the Apple II.

So what were the faults of the original ACI design ?

Well, the "volume indicator LED" almost never worked, so this alone would create phonecalls from desparate users. But it's not an essential feature to read tapes. What really crippled the original ACI is the impedance imbalance in the differential input signal path to the comparator, which only manifests when the cassette recorder is plugged in.

Impedance imbalance in a differential signal path is able to convert common mode interferers (such as the noise / ringing on the power supply and ground return) to a differential disturbance of the wanted input signal. And if that disturbance is large enough, bad things will happen. This one circuit design mistake from the "analog electronics realm" - obviously, unknown territory for even the most brilliant digital designer - was fatal for the success of the ACI, and, by extension, to the whole Apple-1 system.

A "buyback" never has been the sign of a successful product. (Ouch !)

How the ACI circuit was fixed

In the Gen1 improvement step, I fixed the volume indicator LED circuit and added a synchronizer flipflop to decrease the probability of the firmware using bogus comparision values coming from the PROMs. The impedance imbalance was NOT fixed yet because with the now working volume indicator LED, it was possible to find a volume setting where readback worked reasonably OK, with only occasional errors. Which were caught by the "extended format page" added to the PROMs - essentially, adding the Apple II style checksum to the cassette record blocks. These mods were published on Applefritter to be added to standard ACI PCBs by cutting traces and hand wiring. Later, a PCB layout was made, based on the open source Gerbers, and put as a "freebie" into my famous IC kits - to nudge builders to try them out.

This brought relief, and womewhat better readback results, but some builders still complained. So I decided to root out the problem once and for all.

In this Gen2 improvement step, I modified the input biasing network of the comparator to be impedance balanced when a cassette recorder is plugged in. Note that depending on the cassette recorder (or audio source) and the cable length (don't run it across the living room to the stereo set) the impedance balancing may be less perfect than intended, but we have to be realistic, living in the real world, with real electronic components. Still, the improvement was dramatic - I was able to reduce the hysteresis of the comparator by a factor of six, and this brought a much better sensitivity of the TAPE IN signal. This allows the improved ACI to work at lower volume settings, where typical cassette recorders produce less signal distortions. With the better signal fidelity, and less interference by parasitic common mode to differential mode conversion, the readback reliability was now much better. Another PCB was layouted, this time based on Mike "Newton"'s proprietary Gerbers. He generously granted me the right to put those PCBs into my kits as a test run. The feedback from happy builders was encouraging. Now, after 46 years, the ACI finally worked flawlessly as it should have been from the beginning.

The last - and final - edit to the PCB was done a few weeks ago to make the soldering of the LM4040 shunt regulator SMD easier. No change to the circuit as such. The improved Gen2 PCB always had allowed the use of a SMD Zener diode, or the LM4040, or a specific LDO regulator, for the generation of the 2.5V bias voltage. I have measured all these three options in my lab, and found that their performance is the same as far as readback reliability is concerned. But during the pandemic with its supply chain disruptions, LM4040 had been unobtainable for a while, so the PCB was optimized for Zener diodes, which still were available, but had to be hand sorted for a narrower voltage band. When the LM4040 became available again, I put them into my kits to skip the Zener diode sorting step, but some builders complained about the slanted way to solder the LM4040 in. They found it to be too difficult. So in the final revision of the layout, the footprint of this SOT-23 SMD was optimized for the LM4040 alone. It now fits into the footprint 1:1 without weird soldering tricks. But now, soldering in a Zener diode would be more awkward.

I consider my work on improving the Apple-1 motherboard and the ACI to be complete now, after incremental improvements over 4 years. It was a nice pastime during the pandemic which kept me busy, which was good. All what remains to be done is to get my other three projects for the Apple-1 into their final shape - the DRAM expansion card, the color graphics card, and the floppy disk controller card. I also have plans for a game controller add-on which brings joysticks and sounds. But don't hold your breath. I'm busy with my other hobbies, too.

For those who are interested in how the ACI compares to other cassette interfaces of the mid to late 1970s:

The "Kansas City Standard" with a measly 300 bits per seconds was five times slower than the ACI, but much more robust. The irony is that without the impedance imbalance bug, Woz' ACI would have blown them out of the water.

At the same time, here was the notorious Tarbell cassette interface for the S-100 bus, which claimed faster speeds of "up to 540 bytes per second"), but used much more hardware, see:

https://en.wikipedia.orgwiki/Tarbell_Cassette_Interface

According to "Letters to the Editor" in various computer magazines of the time, the success with the Tarbell interface was mixed, and the high speed (540 bytes per second = 4320 bits per second) rarely could be obtained. IIRC, Don Tarbell offered "free of charge" mods to the buyer's cassette recorder, and, also from my memory, he later also sold already modified cassette recorders, which - hopefully - could achieve the advertised speed.

The Commodore PET-2001 had a 1500 bit per second cassette interface, in par speedwise with the ACI, but they recorded everything twice, so the resulting loading time for the same amount of data was twice the loading time for the ACI. And I had my own hands-on experience with the PET, although I never owned one, and I had my fair share of tape loading problems with it. I think the Gen2 improved ACI has a better tape loading reliability than the PET in its original form.

The original Tandy / Radio Shack TRS-80 with the level I BASIC ROMs had only 250 bits per second and despite this ridiculously slow speed the tape readback was unreliable and very sensitive to the volume setting of the cassette recorder (where did we have that, too ?). They even had a substitute for the "volume indicator LED", which was a blinking character on the screen - and this also gave deceptive and erratic information. But Tandy improved their cassette interface over time, and it eventually did reach 1500 bits per second with reasonable readback reliability.

So, again, Woz was the innovative genius who had the 1500 bits per second cassette interface years before the competition, and without the (easily avoidable) bugs in the comparator input network it would have been reliable from the beginning. And it used a minimum amount of hardware. Compare the ACI with its six ICs to the photo of the Tarbell interface card in the above link.

So, the ACI story now has been told from all angles. It was a fun mission for me to improve it to what it should - and could - have been from the beginning, back in the year 1976. I think if Woz had had a seasoned analog / mixed signal circuit design engineer at the time he designed the ACI, it would have been without the faults discussed above. The 741 opamp based circuit in the Apple II got it right - and still uses fewer passive components than the ACI. I wonder who designed this circuit for Woz. It is very elegant and has some hidden features only analog IC designers can see and appreciate. So IMHO, it wasn't conceived by a pure digital designer.

- Uncle Bernie

Surface-mount "Flat-pak" components existed as far back as the 1960s, but given their mil/aerospace pedigree I'm not sure they would have ever found their way into a garage product such as the Apple I. Still it's interesting to speculate.

Lots of interesting info, thanks!

I know a little bit about this guy who made these tests, he's from Poland. Good work! By the way, his github page also has a couple of interesting maps, I've posted links in the FB group but not here it seems.

https://github.com/flowenol/apple1cartridge

https://github.com/flowenol/apple1serial